Before sharing how to perform water resistance testing on solid wood laminate splicing glue, we must first understand what is solid wood laminate splicing glue. Why is solid wood laminate splicing glue water-resistant? Then let’s find out, what are the Japanese JAS boiling water immersion peel test standards. What kind of results can meet the JAS test standards?

What is solid wood laminate splicing glue

Solid wood laminate splicing glue looks like a milky white liquid from the outside. It is mainly used for splicing laminated lumber, solid wood (hardwood, softwood), and other wood products. It is a chemical adhesive product. The chemical name is polyvinyl acetate emulsion.

It has the advantages of high bonding strength, temperature resistance, and solvent resistance. When the solid wood laminate splicing glue is used as the main agent glue mixed with the hardener, it will also have certain water resistance.

Why is solid wood laminate splicing glue water-resistant

After the wood is bonded with splicing glue, the adhesive film itself also has a certain degree of water resistance. In practical applications, it is mixed with a hardener and used. The water resistance and bonding strength of the glue with the hardener are greatly improved, and the curing time will also be accelerated.

What is JAS Boiling Water Immersion Peel Test Standard

JAS boiling water immersion peel test standard is a water resistance test standard proposed by Japan. Its water resistance test results of glue are widely recognized internationally.However, many wood manufacturers, do not necessarily know how to test the paneling effect of the boards after using solid wood laminate splicing glue. Let me give you a brief explanation of the JAS testing standards:

1.Sampling and sample specifications

In the sample wood that has been bonded with solid wood laminate splicing glue, randomly select it from the sample. The sample must be cut along the direction of the wood fiber, with a length of 75 mm.

2.Test method

1. Curing the specimens bonded with splicing glue at room temperature for 7 days.

2. Use a chisel to cut the sample along the glue line and start testing the wood breakage rate.

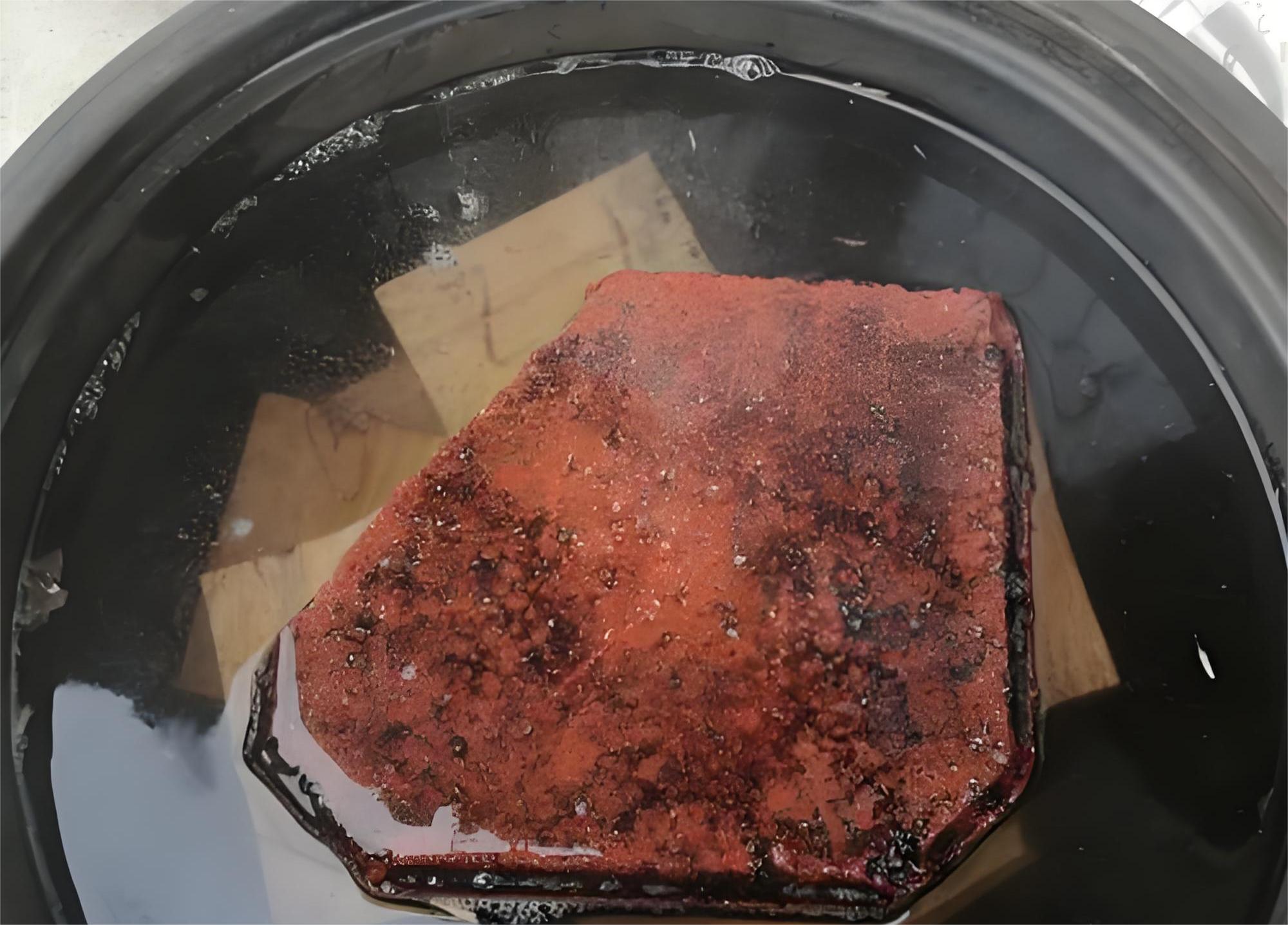

3. Soak the sample in boiling water for 4 hours.

4. Soak the sample in cold water at 10-25℃ for 1 hour.

5. Then place the sample in an oven at 70°C for more than 18 hours to reduce the moisture content of the sample to the pre-test standard.

6. Check the peeling of the glue line again and record the cracking length of the glue line.

3.Calculation standard for glue line cracking rate

Cracking rate (%) = (total length of cracked glue lines at both ends of the sample/total length of glue lines at both ends of the sample)*100%

What kind of results can meet the JAS test standards

The cracking rate of the glue line shall not be greater than 10%, the cracking length of each glue line shall not exceed 1/3 (the cracking length of the glue line is less than 3 mm and can be ignored), and the overall wood breakage rate shall be less than 75%. Only such a result can meet the requirements. According to the standard JAS test, it is a solid wood laminate splicing glue with qualified water resistance.