As an environmentally friendly water-based glue, vacuum membrane glue is popular among consumers as people pay more and more attention to the concept of environmental protection. This glue can be used to bond various materials such as PVC film and PET film to particle board, density board, and other boards through hot pressing. The product is mostly used by furniture manufacturers such as door factories and cabinet factories.

Here are some precautions for the use of vacuum membrane glue, including preliminary preparation, spray gun and spray glue, glue use matters, and pressure relief maintenance matters:

1. Preliminary preparations

1.The moisture content of the board should be controlled at 8-12%.

2. The surface of the plate should be flat, and clean, with clear grooves and obvious back-cut grooves.

3. If you need to add a hardener to increase the temperature resistance and bonding strength of the product, the ratio of glue to hardener needs to be controlled at 100:3-5 by weight.

2.Spray gun and glue spraying matters

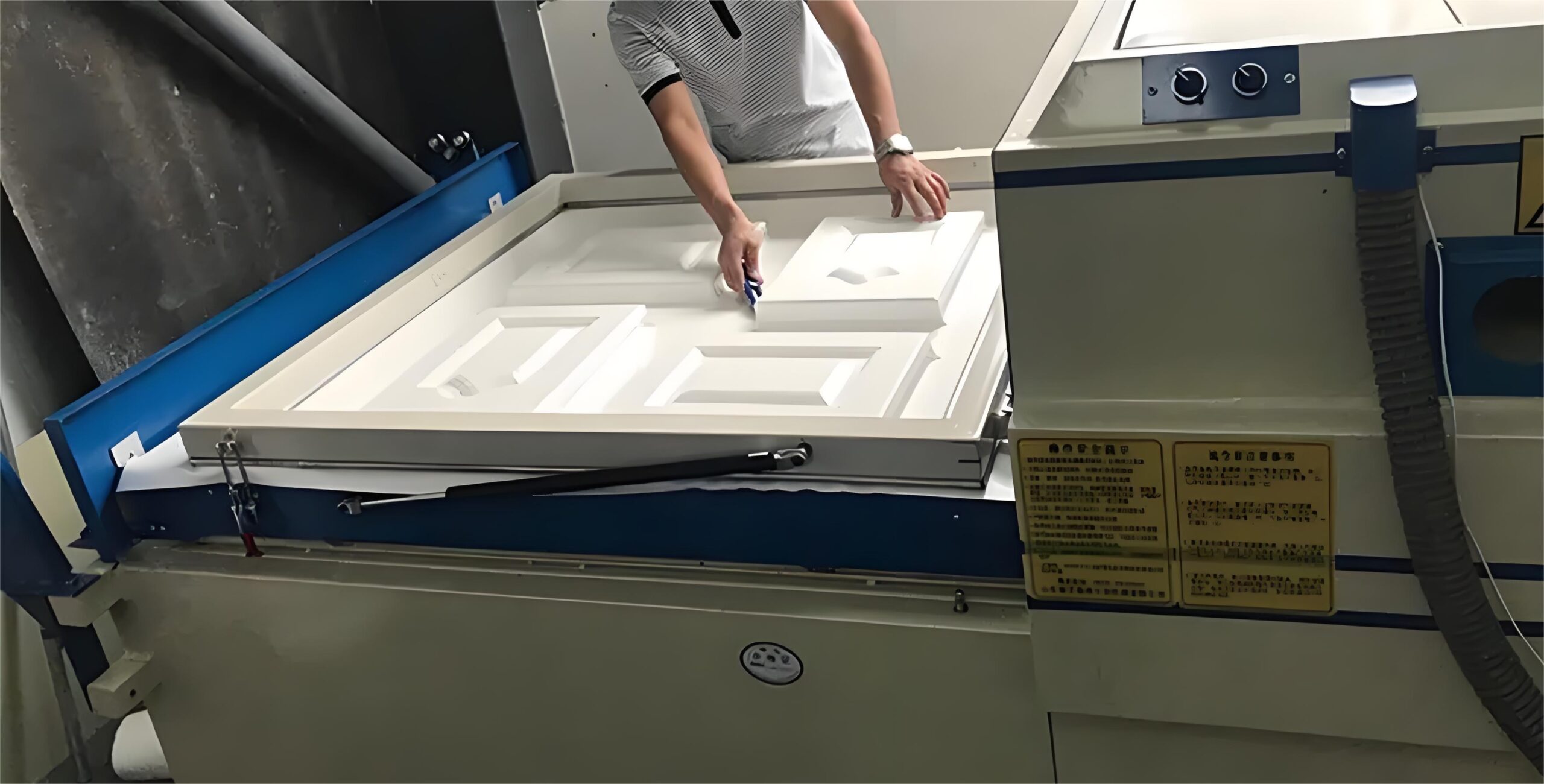

1. Plate cleaning: Clean the plate with air before lamination and lightly polish it if necessary.

2. Spray gun caliber 0.5-1.5mm; air pressure 3-4kgf/cm².

3. The spray gun nozzle should be 150-250mm away from the sprayed surface and move in a straight line to ensure uniform thickness of the vacuum membrane.

3. Precautions for using glue

1. Drying time: At 25℃, it must be used within 30 minutes; at 35℃, the glue can be completely dry in 15 minutes. The sooner it is used, the better.

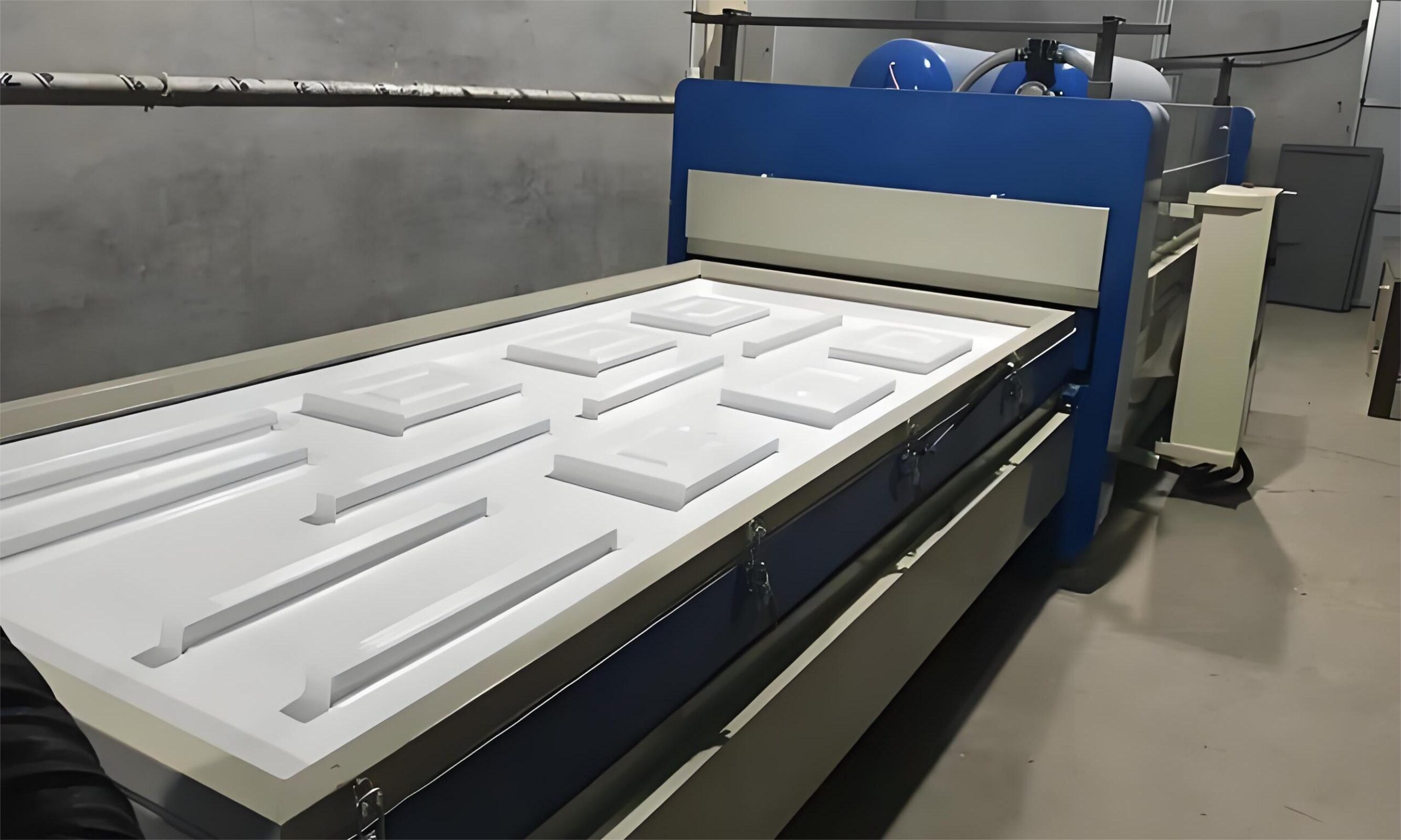

2. Vacuum membrane pad board: The pad board area must be smaller than the workpiece, the pad thickness must be greater than the workpiece thickness, and the workpiece spacing must be greater than 2 times the workpiece + pad height.

3. Base material and ambient temperature: 15-25℃; Gluing amount: 60-80g/m² for surface, 80-120g/m² for edge and contour; Glue layer pressure: 2-18kgf/cm²; Pressure time: 1-4min; PVC softening temperature: 80-110℃.

4. Selection of adhesive for bonding leather: The surface tension of the leather should be between 34 and 36 dynes.

5. Equipment parameters: Activation temperature: 55-65℃; Activation time: 5-15 seconds (the thicker the Pvc film, the longer the time); Heating temperature: 100-180℃ (the thicker the Pvc film, the higher the temperature); Heating time: 90-240 seconds (the thicker the leather, the deeper the groove, and the thicker the board, the longer the time); Cooling time: 10-30 seconds (the lower the air temperature and the higher the heating temperature, the longer the time).

4. Pressure relief maintenance

1. After the product leaves the negative pressure machine and the positive and negative pressure machine, it must be cut only after the temperature drops to no more than 10°C above room temperature.

2. After pressure relief, it should be left for some time (more than 24 hours in winter and more than 18 hours in summer) before entering the next processing step.

3. When testing is required, please test at least 3 days later to ensure the accuracy of the test results; for strict testing, please test after 5 days.