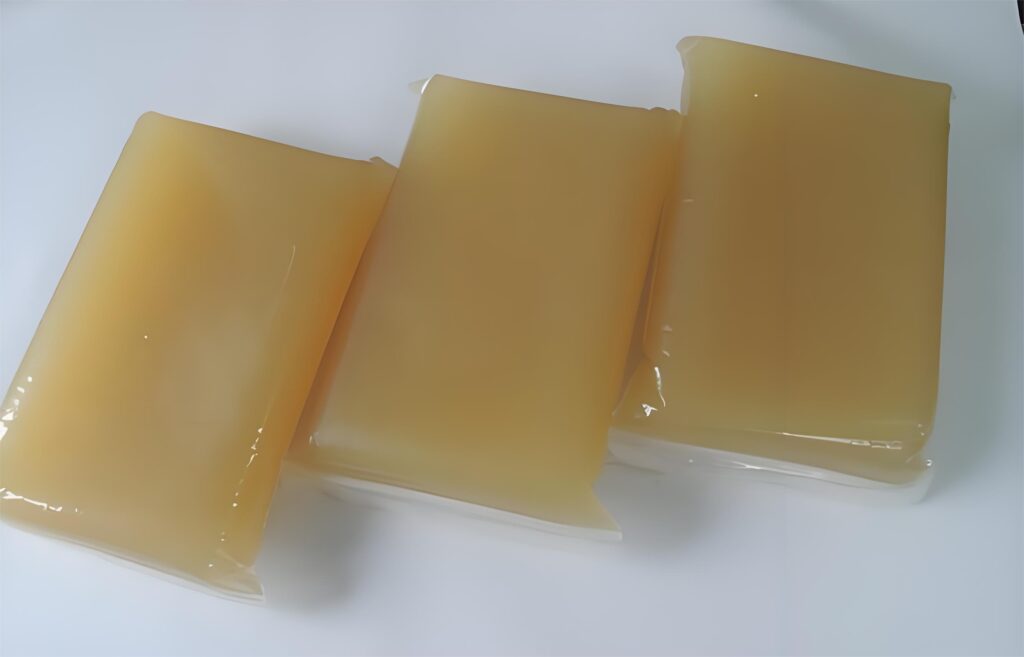

Jelly glue (also known as animal protein glue) is mostly used for gift boxes, wine boxes, cosmetic boxes, tea boxes, hardcover book covers, photo albums, stamp albums, folders, dictionaries, and other covers. It is a safe and environmentally friendly adhesive that printing and packaging factories need to use. The reason why jelly glue is so popular among packaging manufacturers must have its corresponding advantages. Below, we will share with you the advantages of jelly glue used in printing and packaging and the precautions for use:

1. What are the advantages of jelly glue

The chemical bonding principle of jelly glue is that the volatilization of internal water causes the polymer to rely on the tension between each other to tightly bond the two substrates. Therefore, after drying, good quality jelly glue can have a lasting bonding force and can keep the bonded paper from falling off for a long time. At the same time, because the glue can be dissolved in water, it can be easily cleaned as long as it is melted with hot water. Therefore, the manufacturer’s cleaning and sanitation during the production process is also well solved.

Since the main component of jelly glue is animal protein, it does not contain benzene, formaldehyde, and other chemical solvents, and will not pollute food and packaged items, so it is non-toxic and environmentally friendly. Products made with jelly glue have a small deformation rate, are not easy to mold or bubble, and can also enhance the stiffness of paper products. It also has a certain degree of softness, making it difficult to break the frequently folded parts of hardcover books, recipes, dictionaries, etc.

The above-mentioned are the advantages of jelly glue. Because of these outstanding advantages, it is deeply loved by manufacturers.

2. Precautions for using jelly glue

If you are using jelly glue for the first time, you should clean the glue pot and glue tank in advance. After cleaning, put the glue into the glue pot of the glue coating equipment, add a small amount of water to dilute it, and the best amount of water is 5%-10% of the weight of the colloid. Make sure it can be dissolved at a temperature of 70-80℃. Wait until the glue is completely dissolved into liquid before using it on the machine.

The operating temperature in summer and winter is different. In winter, due to the overall ambient temperature, to ensure that the glue blocks can be completely dissolved, the temperature needs to be slightly higher than in summer. When the ambient temperature in winter is less than 10°C, the temperature of the glue machine needs to be set at 80°C-90°C.

When the ambient temperature in summer is higher than 25°C, the temperature only needs to be set at 70°C-75°C (due to differences in temperature tests of different glue equipment, and in extremely low or high room temperatures, the difference between the temperature setting of the glue equipment and the actual temperature of the glue liquid may also change, and the specific temperature should be determined according to the on-site temperature).

After the jelly glue on-site dissolution equipment is shut down, the colloid temperature will drop and it will solidify again. It only needs to be reheated and melted before the next use. However, after repeated heating and cooling, the viscosity of the colloid will be affected. It is recommended that manufacturers put in an appropriate amount of glue blocks according to the actual processing volume so that the amount used is melted. After the machine is shut down after getting off work, please clean the rubber roller, rubber hose, and glue pump immediately to avoid damage to the rubber roller and blockage of the rubber hose and glue pump after the glue solidifies.

The above are the advantages of jelly glue and the precautions for use. I hope it will be helpful for you to choose and use jelly glue.