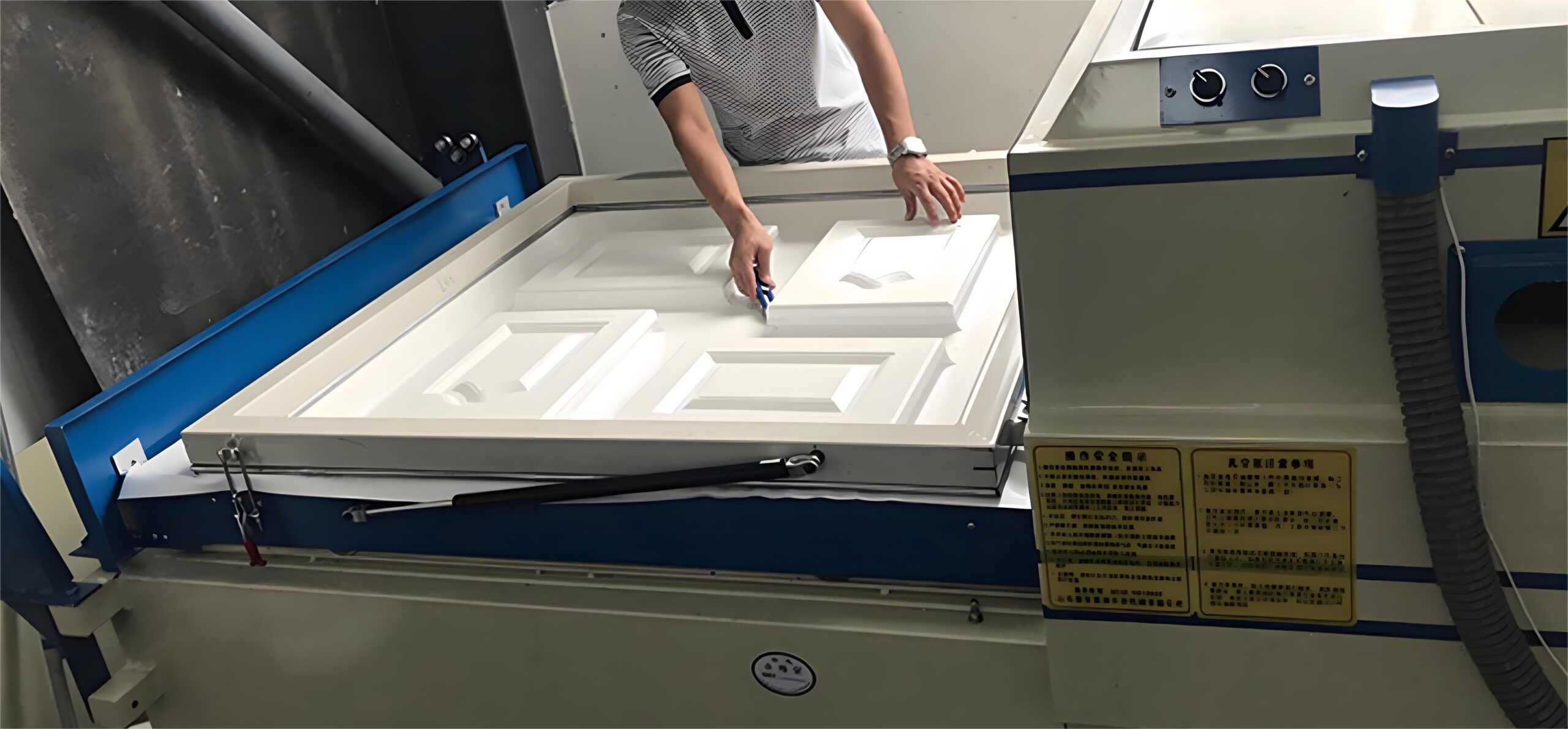

Vacuum membrane wrapping glue is a non-toxic and environmentally friendly water-based adhesive. It is widely used in the vacuum membrane wrapping composite process of flat or grooved surfaces. It can absorb PVC and other materials on density boards, particle boards, artificial boards, and other boards through the blister machine. Wooden door factories, cabinet factories, speaker factories, computer desks, and other manufacturers will use this glue.

However, many manufacturers are prone to pitting due to not paying attention to certain details during production. Below, I will share with you the main reasons why customers use vacuum membrane wrapping glue to get pitting:

1. There is a lot of dust in the production workshop, which causes dust on the PVC film or board.

2.The worker sprayed too much glue, causing too much glue to accumulate on the board.

3.The glue itself contains too much water, causing the fibers on the board to absorb too much water, causing the fibers to swell and stand upright.

4.The glue is not filtered properly, the particles are too large or too thick.

5.Other impurities (such as dust, sawdust, etc.) are mixed into the vacuum membrane wrapping glue.

6.The atomization performance of the glue spray is poor, and the glue particles are obvious when sprayed on the board.

7.The board was not polished properly in the early stage, resulting in particles or unevenness on the plate.

8.The fiber of the board itself is too coarse and it is still very rough after polishing.

9.The worker sprayed too far away from the board, causing the glue to lose moisture when sprayed onto the board surface, and the glue particles floated on the board surface to form particles.

10.After spraying vacuum suction plastic, inadequate protection during the drying process resulted in dust or sawdust adhering to the surface of the board.

11.The worker touched the glue that had not completely dried with his hands, resulting in clear finger marks on the board.

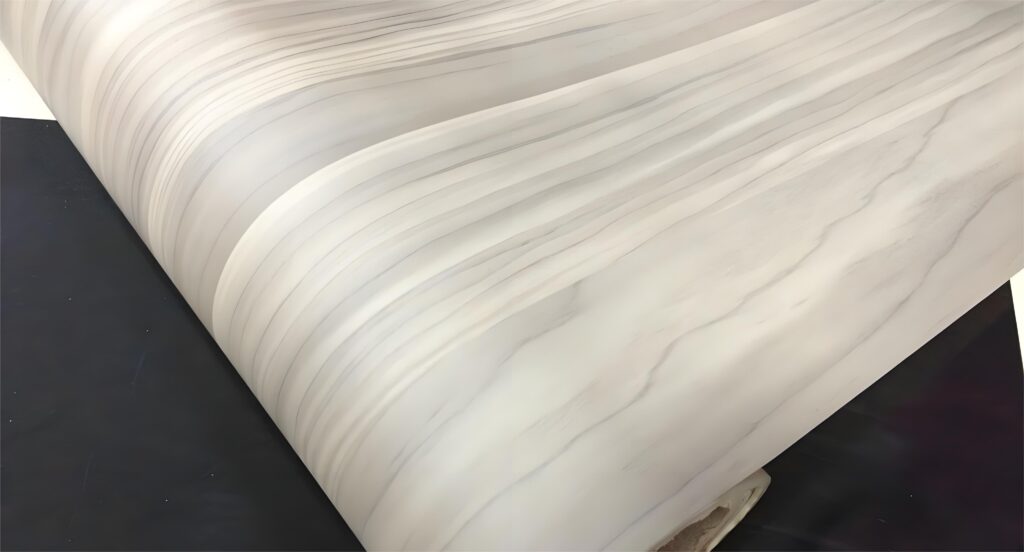

12.The quality of PVC film itself is poor, with particles on the surface, which can also cause pitting.

When you encounter pitting when using vacuum membrane wrapping glue, you can investigate each of the 12 reasons described above and solve the problem smoothly.