Solid wood splicing glue should be familiar to solid wood furniture manufacturers or wood processing manufacturers. It is a water-based environmentally friendly adhesive mainly used for splicing between boards. Water-based adhesive is a kind of glue that forms bonding strength by evaporating water and penetrating wood. Therefore, many factories do not pay attention to some details of gluing during actual use, resulting in the situation that the splicing glue does not dry or dries slowly. Next, I will share with you the reasons and solutions for the splicing glue not drying or drying slowly:

1. Improper hardener ratio

The purpose of adding hardener (isocyanate MDI) to solid wood glue is to make the glue cure faster and improve the water resistance and weather resistance of the glue after film formation. However, many manufacturers use the wrong ratio of hardener or add too little hardener, which will cause the glue to dry slowly. The correct ratio of glue to hardener should be 100: 12-15(by weight).

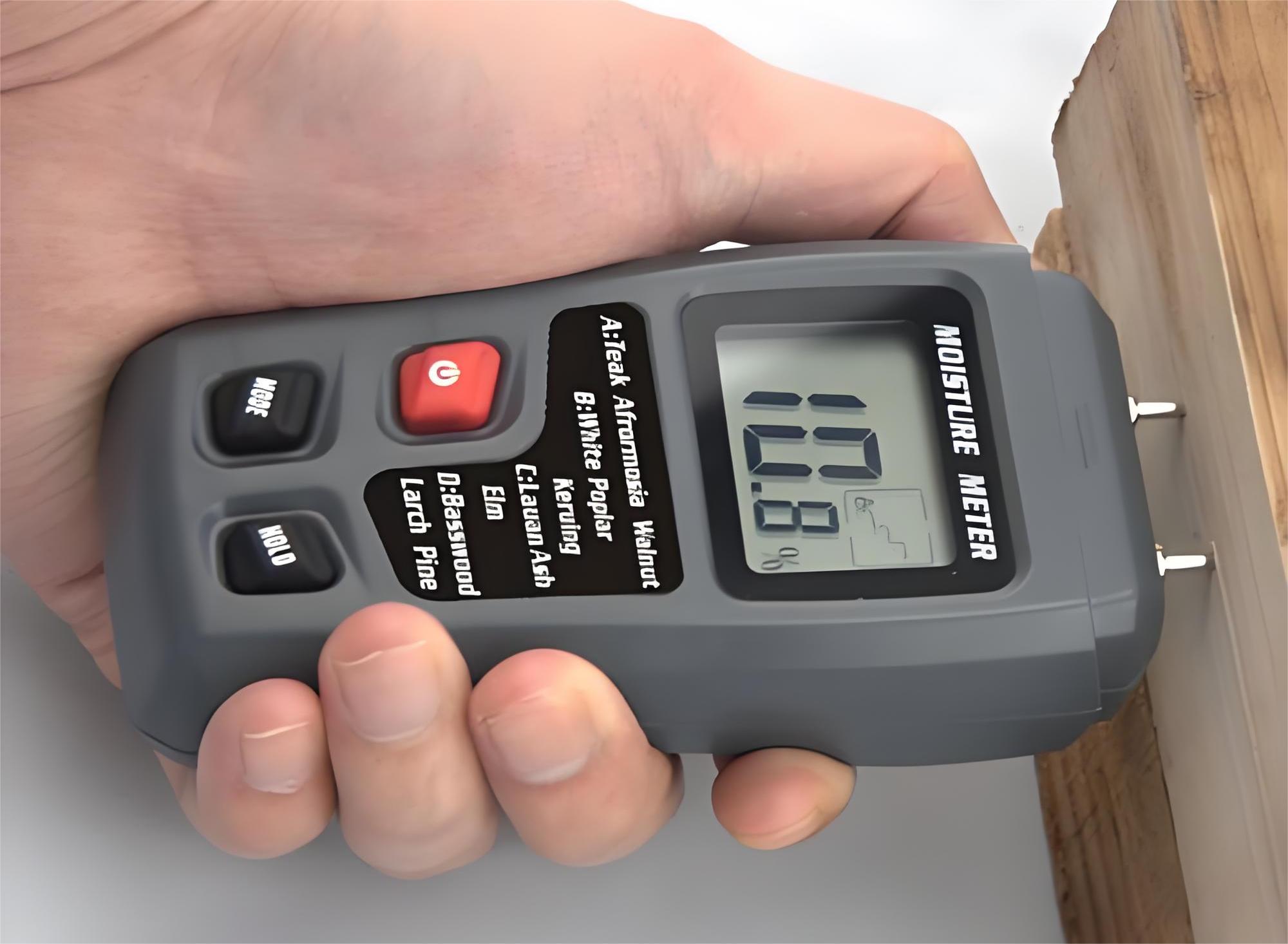

2. The moisture content of the substrate is too high

If the moisture content of the wood itself is too high (greater than 12%), it will affect the volatilization of the glue itself and its penetration into the wood. The reasonable moisture content of wood should be controlled at 8-12%. Therefore, manufacturers should dry the wood before using solid wood splicing glue to ensure that the moisture content of the base material is within a reasonable range.

3. Insufficient drying time

After the glue is applied to the spliced wood, it takes a certain amount of time for the glue to evaporate naturally. Therefore, after the wood is pressed for 2-4 hours, we recommend that it should be left to age naturally for a period of time (more than 24 hours in winter and more than 18 hours in summer) so that the glue can reach its best performance before entering the next processing step.

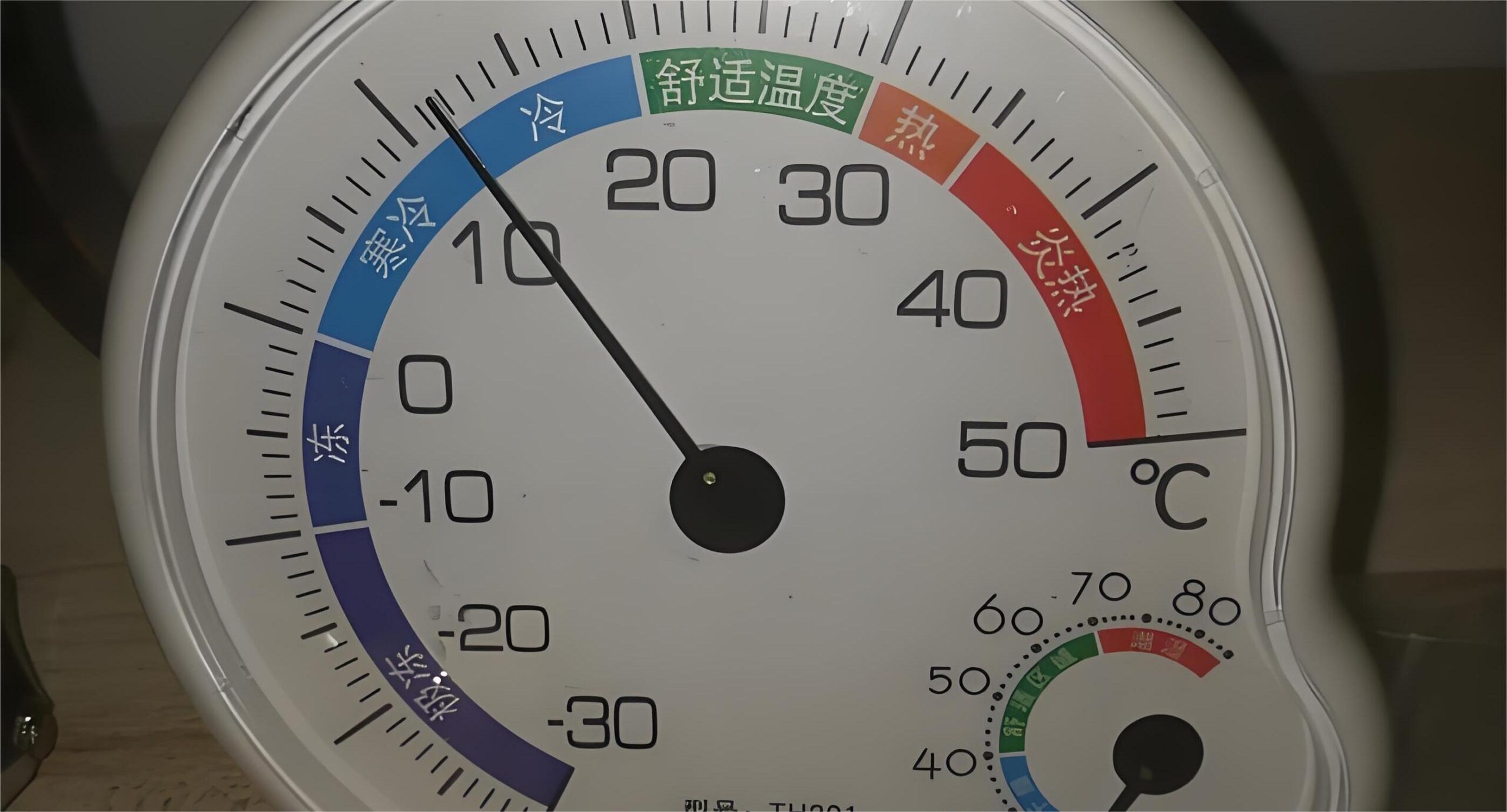

4. The ambient temperature is too low or the humidity is too high

Due to the low ambient temperature or high humidity, the volatilization of water in the glue will also be affected. For this harsh operating environment, manufacturers can consider extending the drying time of the product, increasing the ambient temperature, and appropriately increasing the proportion of hardener. These methods can make the glue for the panel dry faster. The normal ambient temperature for gluing should be above 10°C and the air humidity should be 40-80%.

5. Too much glue applied (thick overflow glue line)

Too much glue applied to spliced solid wood will cause the glue to not dry or take a long time to dry. We generally recommend that manufacturers control the amount of glue applied and clean up the excess glue after pressurization. The normal amount of glue applied: 200-250 g/㎡ for single-sided glue and 120-150 g/㎡ for double-sided glue.