Wood assembly glue refers to an adhesive used for bonding solid wood at 45° or 90° angles, such as tooth joints, finger joints, and mortise joints of furniture. Door factories, solid wood furniture factories, handicraft factories, display cabinet factories, picture frame factories, etc. All use assembly glue. Next, I will share with you some precautions for using wood assembly glue:

1. Moisture content of wood

For wood, the first thing to pay attention to is the moisture content of the wood. The moisture content of the wood used for assembly should be controlled at 8-12%, and the moisture content between adjacent components should not exceed 3%. If the moisture content of the wood is too high, it is not conducive for the glue to penetrate the wood, thus affecting the bonding strength of the glue. If the moisture content is as high as 12-15%, the pressurization time needs to be extended to facilitate the glue to penetrate the wood and solidify, and the environmental conditions (temperature humidity, etc.) of the glue application site need to be considered.

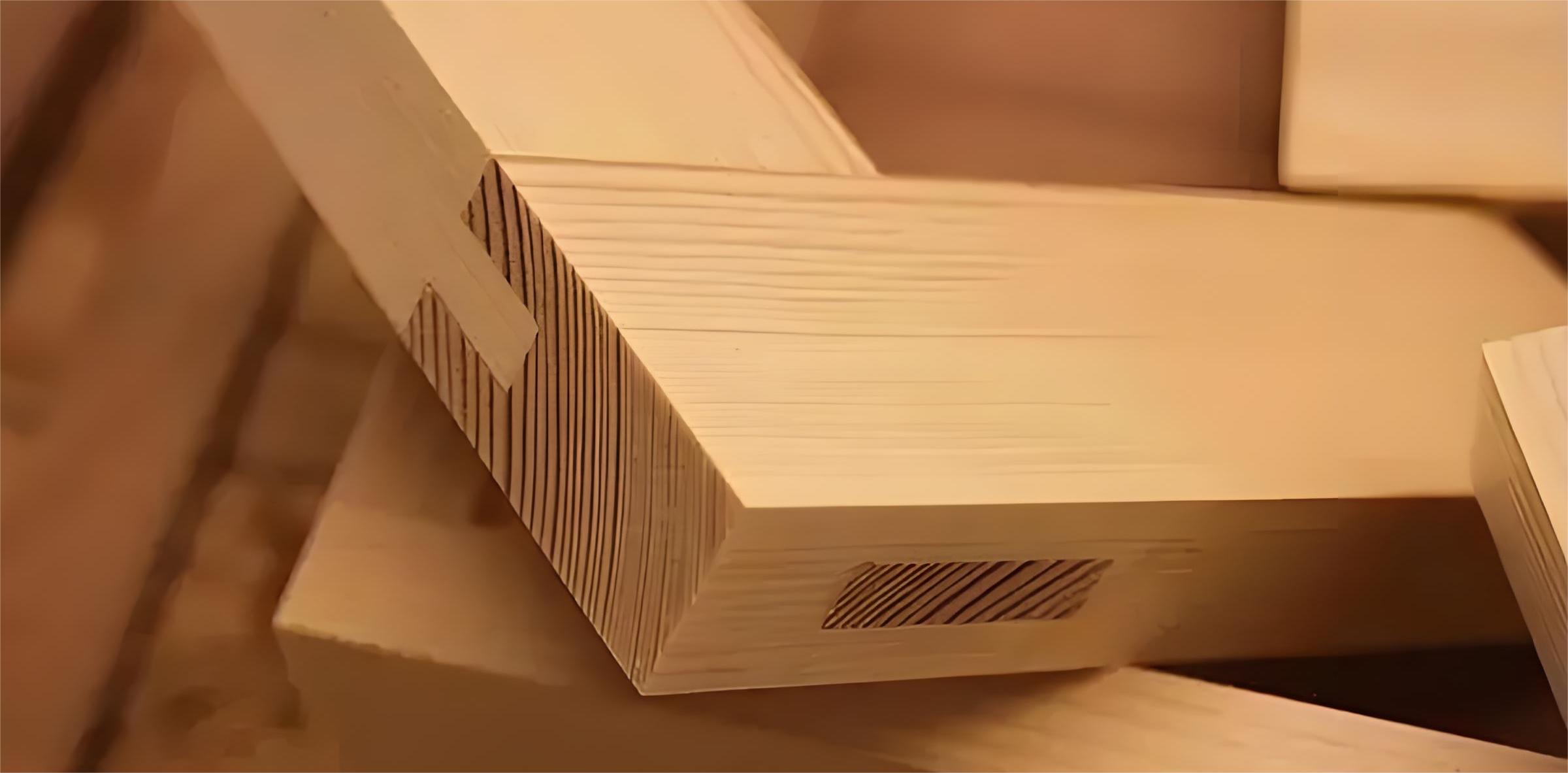

2. Precision of assembly parts

The contact surface of the wood assembly must be processed with good accuracy and free of saw marks, planing marks, carbonization marks, etc. The processing precision should be controlled within 0.05-0.1㎜ to facilitate the effective penetration and contact of the assembly glue.

3. Operating environment temperature

The ambient temperature at the wood assembly site should be controlled at 10-35°C. Too low a temperature (less than 10°C) is not conducive to the curing of the glue. In comparison, too high a temperature (greater than 35°C) will cause the surface of the glue to form a film and dry before the glue can fully penetrate the wood, shortening the open time of the glue and affecting the bonding strength.

4. Correct amount of glue

It is recommended to apply glue on both sides (i.e., the joints, tendons, and mortise joints all need to be coated with glue; the amount of glue used is 200g-250g/m2). The shorter the open time after applying the assembly glue, the better, to avoid the glue being exposed to the air too much and losing its adhesion. The amount of glue applied can also be appropriately increased when the temperature is high.

5. Correct way to apply pressure

Apply pressure (the pressure must be balanced when applying pressure, pressure: 0.5-1.5mpa/cm², it is best if a small amount of glue can be squeezed out of the assembly), no pressure or too low pressure will affect the bonding strength; remove the pressure and turn to the next processing step, and ensure 12 hours of natural aging time, because the water-based adhesive takes at least 24 hours to cure in dry weather.

The above 5 points are some things you need to pay special attention to when using wood assembly glue. If you have any questions when using glue, you can also consult us.