PUR (Polyurethane Reactive) hot melt adhesive is a new type of environmentally friendly adhesive product that has become popular in the woodworking furniture manufacturing industry in recent years. Currently, PUR hot melt adhesive is used in the furniture industry mainly in three processes: flat lamination, wrapping, and edge banding. Manufacturers using EVA hot melt adhesive often ask us about the advantages and disadvantages of PUR hot melt adhesive over EVA hot melt adhesive. As a glue manufacturer with more than 10 years of experience in hot melt adhesive research and development, production, and manufacturing, we will now answer this question.

PUR hot melt adhesive is a reactive polyurethane adhesive that forms adhesion mainly through chemical reactions with water in the air. First, let me share with you its advantages:

1. Compared with traditional EVA hot melt adhesive, its bonding performance, high and low-temperature resistance, weather resistance, solvent resistance, and other aspects will be better.

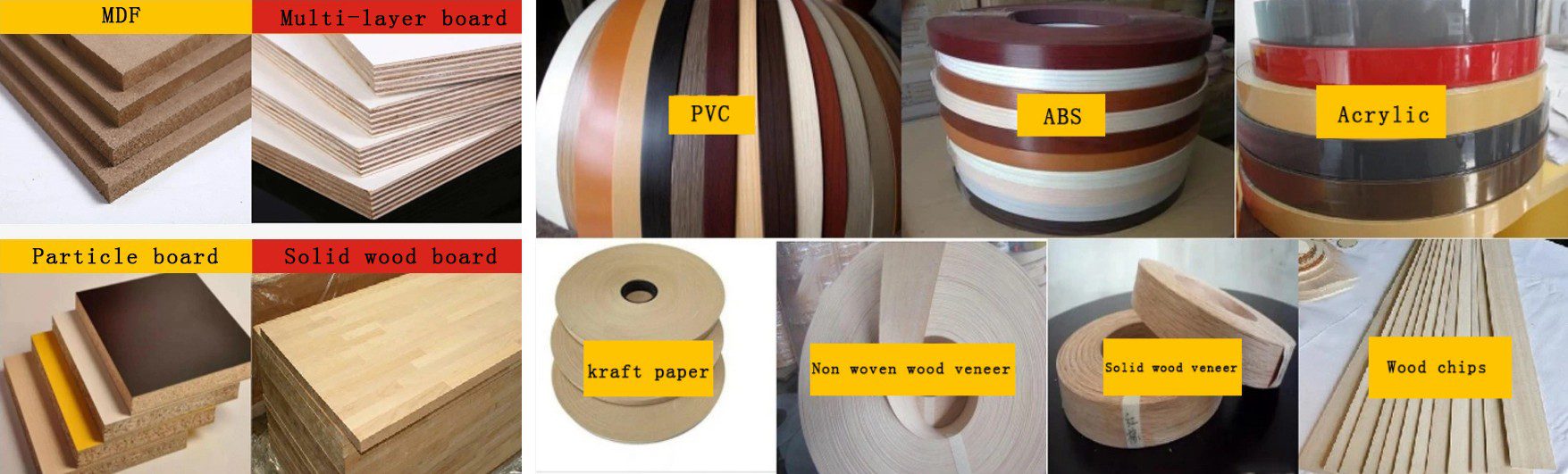

2. Because PUR hot melt adhesive has a strong penetration ability, its application substrates that can be bonded are more extensive than traditional EVA hot melt adhesive.

3. Due to its excellent bonding and coating properties, the amount of glue used can be reduced by two-thirds compared to traditional EVA hot melt adhesive.

4. The solid content of PUR hot melt adhesive can reach 100%, and the product is green and environmentally friendly after curing.

After talking about the advantages of PUR hot melt adhesive, let’s talk about its disadvantages:

1. Compared with traditional EVA hot melt adhesive, gluing equipment requires more investment to upgrade to professional edge banding equipment.

2. The requirements for humidity (greater than 50%) and temperature (greater than 5°C) in the operating environment are more stringent.

3. After the product is cured, it cannot be reversed, and the equipment will be more difficult to clean than traditional EVA hot melt adhesive.

4. The unit price of the product is several times more expensive than EVA hot melt adhesive, but due to the small amount of glue applied, this disadvantage can be ignored.

The above is the knowledge sharing about the advantages and disadvantages of PUR hot melt adhesive. I hope it can be helpful to everyone when choosing PUR hot melt adhesive. If you have other questions about PUR hot melt adhesive, you can consult us directly.