Pay attention to details when using woodworking glue

in actual production, furniture manufacturers need to pay attention to what they need to pay attention to when using woodworking glue. Let me share with you below.

in actual production, furniture manufacturers need to pay attention to what they need to pay attention to when using woodworking glue. Let me share with you below.

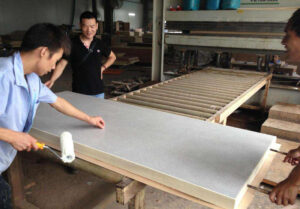

We have always recommended that the ambient humidity is 40-60% as the optimal ambient humidity for solid wood laminating. However, if you need to perform a lamination process when the humidity in the air is high, we recommend that furniture manufacturers use solid wood laminated adhesive when splicing. The following needs to be done:

Some friends cannot distinguish specific categories and different uses when consulting our products. Let me explain to you the differences between woodworking glue and white latex glue:

Use a glue gun for spraying. The optimal diameter of the spray gun nozzle is 1.5-2.5mm. If the diameter of the spray gun is too small, it will easily block the spray gun and affect the work efficiency of the workers.

Some customers are prone to blistering when using veneer glue to veneer manual. If they use an iron to iron the veneer surface after bubbling, cracking will easily occur. At worst, the workers will rework, and at worst, the furniture will become unusable. This problem has troubled many customers.

I believe that many manufacturers who need to convert to PUR equipment or are using PUR hot melt adhesive will want to know the usage temperature of PUR hot melt adhesive.

EVA hot melt adhesive application technology for many manufacturers who are using EVA hot melt adhesive for edge banding or even EVA hot melt adhesive carton sealing, they maybe want to know about the EVA hot melt adhesive application technology.

Phone and wechat: +86 137 0239 0495

Email: sales@bluerhino-adhesive.com

We will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.