Hot melt adhesive has always occupied a large proportion of the adhesive field and is mostly used for edge banding of panel furniture. However, manufacturers still encounter various problems in the process of using it, resulting in poor edge banding effect, insufficient bonding strength, and even edge banding falling off, surface scratches, surface ridges, etc. Below, we will share with you the common problems and solutions of edge banding hot melt adhesive:

1. There is no problem after the edge banding is completed, but the edge banding strip falls off during trimming.

Case a: The amount of glue applied is insufficient, resulting in insufficient bonding strength between the substrate and the bonding surface, and the amount of glue applied needs to be increased later;

Case b: The temperature of the substrate (board and edge banding) is too low, which will cause the high-temperature hot melt adhesive to encounter the cold substrate, and the surface will quickly form a film, affecting the bonding strength. Therefore, at a lower temperature, the substrate needs to be properly heated;

Case c: The speed of the machine conveyor belt is too slow, and the glue has cooled down when it encounters the air before edge banding, and cannot reach the required temperature for edge banding. In this case, the machine edge banding speed can be increased or the glue pot temperature of the hot melt glue can be appropriately increased.

Case d: Low ambient temperature and insufficient pressure may also cause the edge banding strip to fall off during trimming. You can consider heating the edge banding workshop and increasing the pressure of the pressure wheel.

2. One side of the adhesive surface has a good effect while the other side has a poor effect

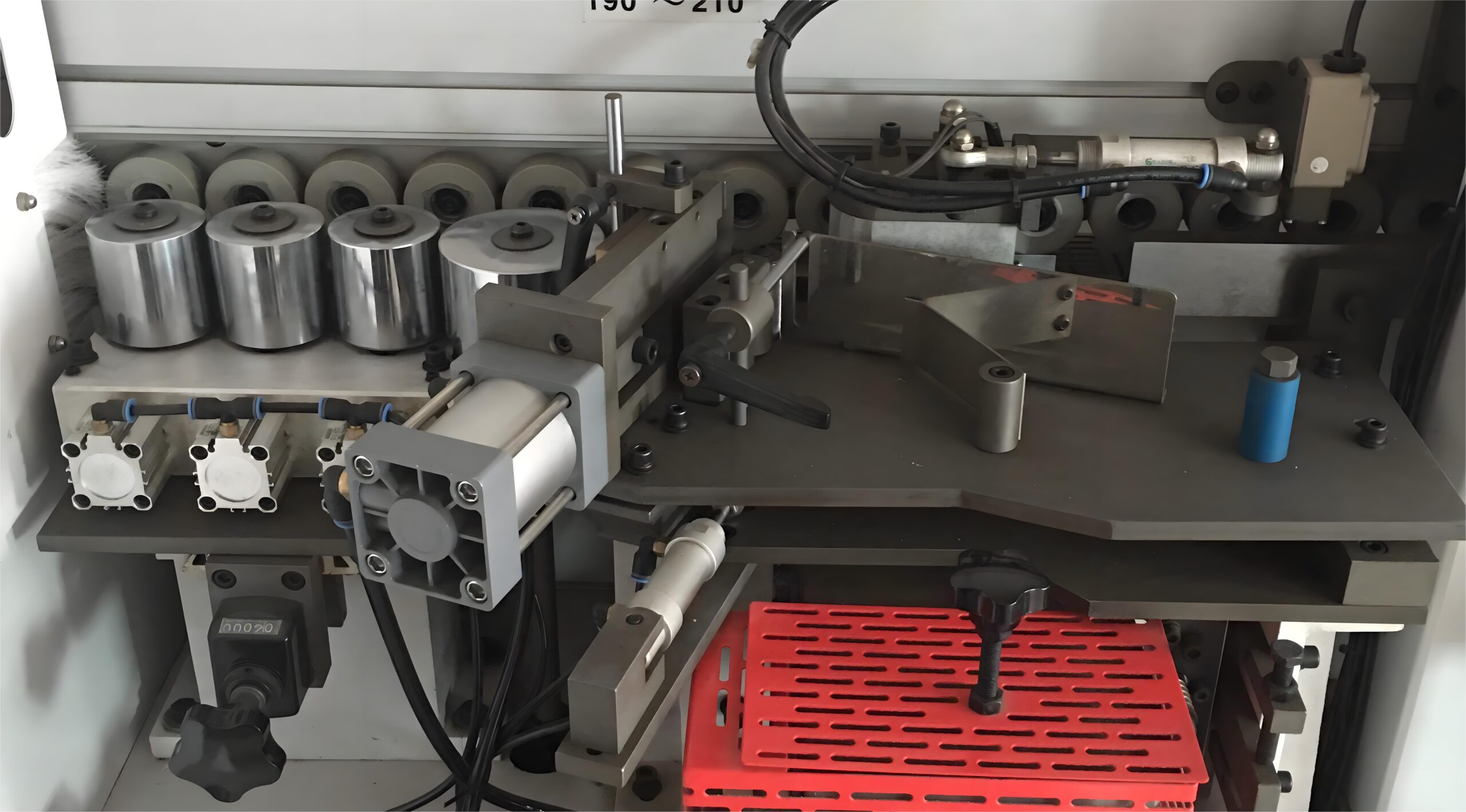

There are generally two reasons for this situation. The first is that the contact between the substrate and the pressure wheel is not good. The second is that the glue coating machine does not coat the glue evenly. In the above two situations, you need to check the equipment condition of the machine and do regular maintenance.

3. The bonding effect of the head and tail of the edge banding is not good

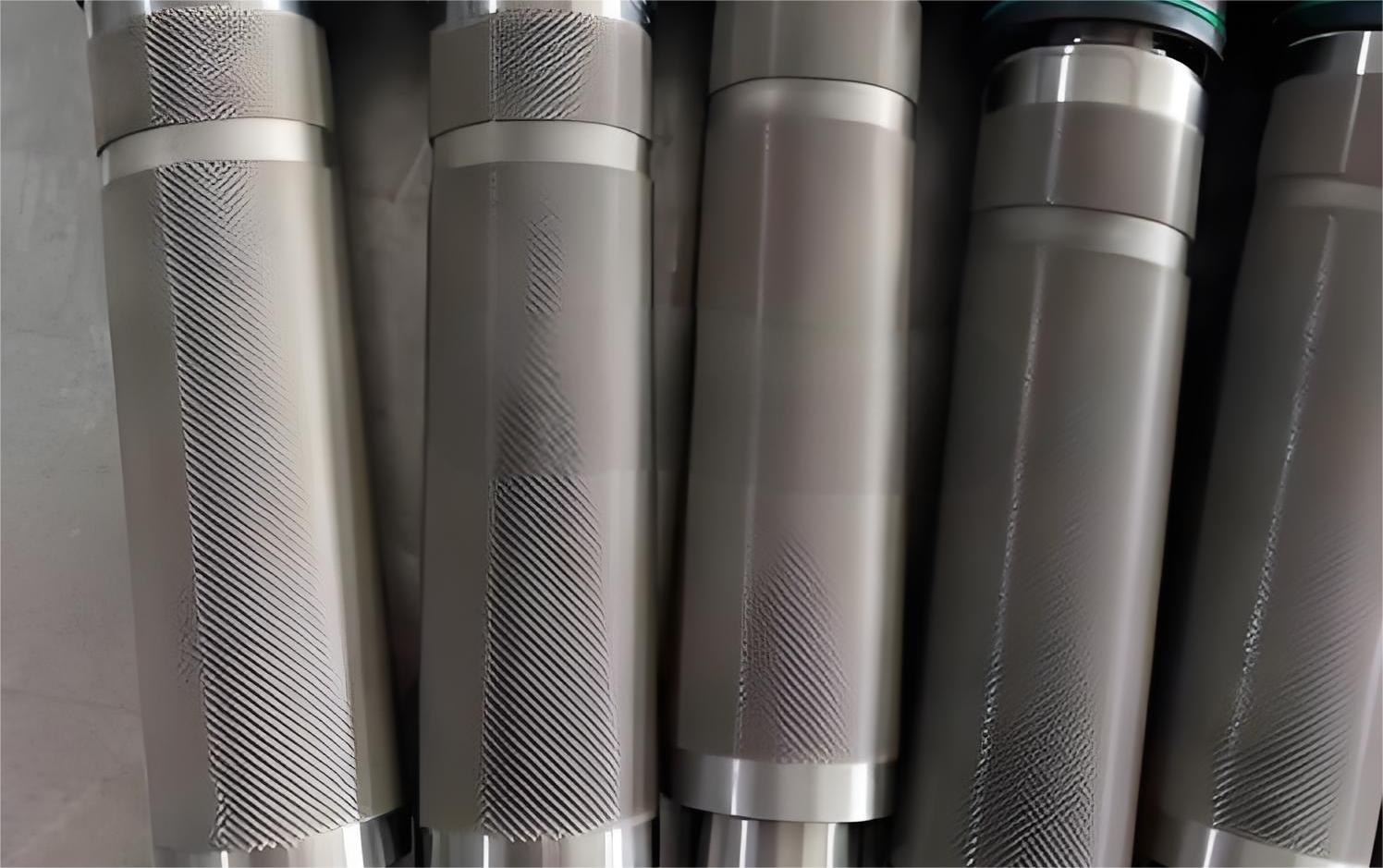

The 5 cm at the head and tail of the hot melt adhesive roller bonding the board is where the effect is often poor, because the pressure at the head and tail is prone to be insufficient, especially when the machine is in high-speed production, the panel and the adhesive roller are prone to jumping, which requires adjustment of the adhesive wheel pressure.

4. There are scratches on the surface after edge banding

This situation often occurs because the edge banding itself is too thin or has poor surface wear resistance. Secondly, the rough edge in contact with the board and the insufficient elasticity of the adhesive film after the hot melt adhesive is formed may also cause scratches. You can consider replacing the appropriate substrate and hot melt adhesive.

5. The edge banding will fall off quickly after edge banding

Case a: Because the temperature of the hot melt adhesive is too high, the product loses its activity, resulting in false adhesion. You can consider lowering the temperature of the glue pot appropriately.

Case b: If the temperature of the substrate, pressure roller, and glue coating environment is too high, it will also have an impact, and the environment needs to be cooled down appropriately.

Case c: The humidity and oiliness of the board itself will affect the penetration of the glue into the board, and will also cause the substrate to fall off quickly after edge banding; the board can be dehumidified and degreased.

6. After edge banding, the surface has ridges or pen-tip shapes

If the surface of the board is not sanded or dusted before edge banding or is contaminated by sawdust during the hot melt adhesive sol, it will cause bumps after edge banding. This kind of situation is very simple to deal with. Sand the board before edge banding and add dust-proof treatment to the hot melt adhesive tank.

The above are some common problems and solutions for edge banding hot melt adhesive. You can adjust and solve them according to your situation.