EVA hot melt adhesive application technology for many manufacturers who are using EVA hot melt adhesive for edge banding or even EVA hot melt adhesivecarton sealing, they maybe want to know about the EVA hot melt adhesive application technology.

Blue Rhino New MaterialsCo., Ltd., as a manufacturer with rich experience in R&D and production of EVA hot-melt adhesives, will share the content of EVA hot-melt adhesive application technology from product principles to applications:

Let’s talk about the ingredients of eva hot melt adhesive first. In terms of ingredients, eva hot melt adhesive is a polymer that does not contain moisture and has 100% solid meltability. It is a solid granule or block product at room temperature. After heating to the melting point, it will become a fluid adhesive with a certain viscosity.

Under normal circumstances, it is light brown translucent or white. The main material component of EVA hot melt adhesive – resin is copolymerized by ethylene and vinyl acetate under high pressure, and then mixed with a certain proportion of tackifiers, viscosity regulators, antioxidants, etc. to make EVA hot melt adhesive.

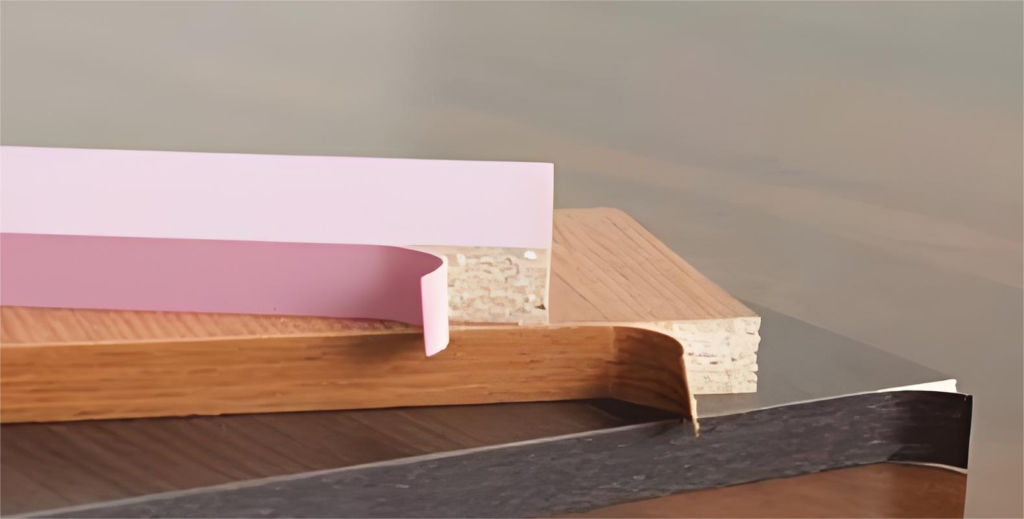

Next, let’s talk about the application of EVA hot melt adhesive. The application of hot melt adhesive is actually very simple. You only need to pass the glue through the melting furnace, heat it to a molten state, and apply the glue to the substrate(base material) by machine or hand. Apply pressure appropriately, and when the temperature cools down, an adhesive force can be formed to bond the substrate(base material).

Specific applications include edge banding and wrapping processes in the furniture industry, label bonding, carton edge sealing and packaging box bonding in the printing and packaging industry, as well as the bonding of maternal and infant diapers. The above is the relevant knowledge of EVA hot melt adhesive application technology.Hope it will be helpful to everyone.