Pur hot melt adhesive is currently the most popular type of adhesive. Its chemical name is moisture-curing reactive polyurethane hot melt adhesive. It is deeply loved by customers in the wood processing industry for its excellent bonding strength, high and low temperature resistance, moisture resistance, and green environmental protection.

Pur hot melt adhesive is very popular in wood processing, decoration, furniture, automobile, and other industries. It is often used for profile wrapping, edge banding, and flat lamination of substrates. We have previously introduced edge banding and flat lamination processes in other blog posts. Next, we will analyze how to choose Pur profile wrapping hot melt adhesive from different angles:

What is Pur Profile Wrapping Hot Melt Adhesive

Pur profile wrapping hot melt adhesive is a moisture-curing reactive adhesive used for bonding wrapping materials (PVC film, veneer, paper, leather, etc.) on the surface of profiles (MDF, wood, aluminum, steel, plastic, etc.). Pur adhesive has excellent bonding adaptability and irreversible degeneration, which can ensure perfect bonding effect on substrates of different materials.

What are the advantages of Pur profile wrapping with hot melt adhesive

Strong bonding force: Compared with traditional adhesives, the tensile strength of Pur-type adhesives is 1.5 times greater.

Wide adaptability: Pur adhesive has extremely strong permeability, which ensures that it can bond to most materials on the market.

Good weather resistance: It does not debond in high and low temperature (-40°C to 120°C) environments, is resistant to solvent corrosion, and has good moisture resistance, making it particularly suitable for outdoor use and in high humidity environments.

The adhesive film is tough: the glue can maintain its elasticity after curing, reducing the probability of the wrapped substrate being deformed after being impacted.

Low glue application amount: Under the premise of ensuring the bonding effect, the amount of glue used is less than that of traditional hot melt adhesive, which indirectly reduces the cost of the product.

Green and environmentally friendly: 100% solid content, no solvent, no formaldehyde, no VOC, in line with environmental testing requirements.

What is the difference between Pur profile wrapping hot melt adhesive and Eva profile wrapping hot melt adhesive

In the past, Eva hot melt adhesive was mainly used for profile wrapping, but with the continuous improvement of Pur adhesive technology in recent years, the stability of the product has become higher and higher. With its excellent bonding performance, manufacturers choose to use Pur adhesive for profile wrapping at an increasing rate. The following is an analysis of the differences between Pur profile wrapping hot melt adhesive and Eva profile wrapping hot melt adhesive:

| Curing Type | Tensile strength | Heat resistance | Solvent resistance | Flexibility | price | |

| Pur profile wrapping hot melt adhesive | Moisture chemical reaction curing | Very strong | Strong, can withstand temperatures above 100°C | Excellent | Excellent | Higher |

| Eva profile wrapping hot melt adhesive | Physical high and low temperature curing | Ordinary | Weak, around 70°C | Ordinary | Ordinary, becomes brittle at low temperature | Ordinar |

A comprehensive comparison of the performance of the two shows that Pur profile wrapping hot melt adhesive is superior to traditional hot melt adhesive in terms of tensile strength, temperature resistance, solvent resistance, flexibility and other aspects. The finished product after coating is suitable for long-term use in high temperature and high humidity environments.

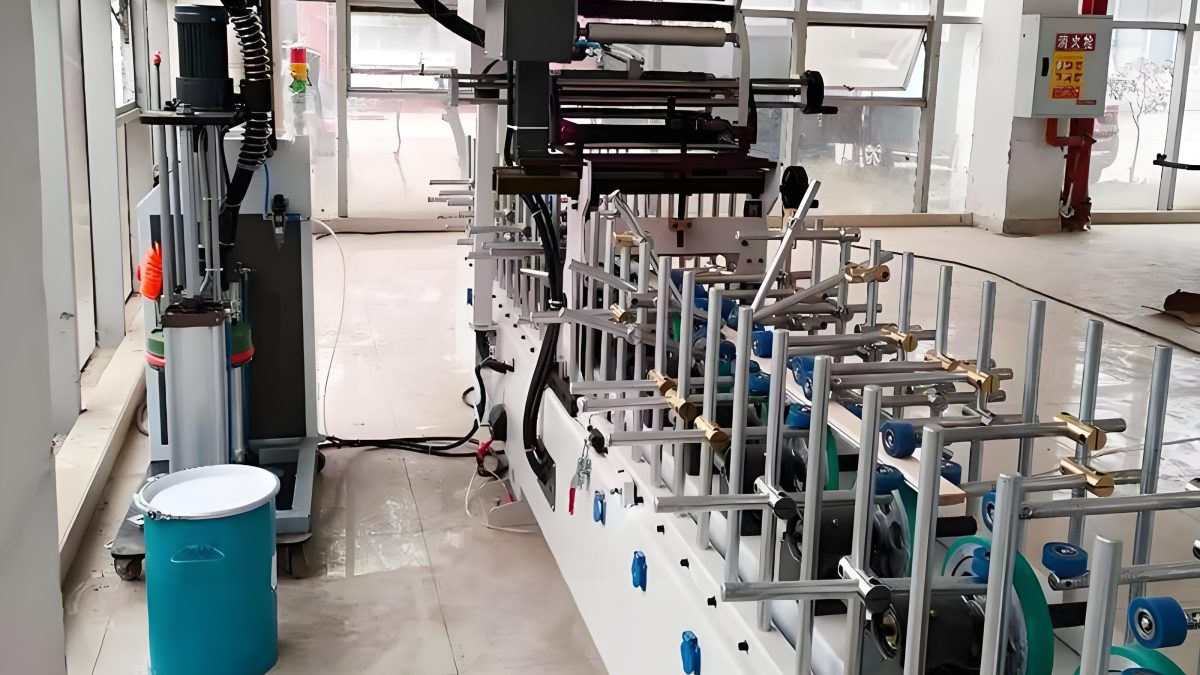

How to use Pur Profile Wrapping Hot Melt Adhesive

Before wrapping the Pur profile with hot melt adhesive, you need to make sure that the type of glue matches the material being bonded. After setting the temperature of the glue melter (110°C -140°C), put the glue into the glue melter in advance to preheat it. According to the shape of the profile, accurately adjust the pressure wheel of the wrapping machine and the amount of glue applied. Special attention should be paid to the temperature (15°C -35°C) and humidity (40%-70%) of the production site environment.

In summary, the best profile wrapping effect depends on precise control of temperature and humidity, reasonable application of glue, and pressing of contours.

What are the common problems of hot melt adhesive for Pur profile wrapping

1. Bubbles appear on the surface of the profile after wrapping:

It may be that the oven tunnel temperature is too low, the angle of the pressure wheel is incorrect, and the bubbles of the glue itself are not released completely.

How to solve the problem of surface bubbles:

Increase the oven tunnel temperature, readjust the angle of the pressure wheel, and squeeze out the glue bubbles before applying glue.

2. Surface material falls off after wrapping the profile:

It may be that the glue type does not match, the melting temperature is incorrect, the ambient temperature and humidity are incorrect, there is a gap between the pressure wheel and the profile, the pressing time is too short, and the amount of glue applied is too little.

How to solve the problem of surface material falling off:

Replace the correct glue type, adjust the temperature of the melting equipment, wrap at the correct ambient temperature and humidity, adjust the angle of the pressure wheel, reduce the speed of profile wrapping, and increase the amount of glue applied.

3. Wrinkles appear on the surface after the profile is wrapped:

It may be due to excessive glue application, incorrect pressure angle of the pressure wheel, or too short pressing time.

How to solve the problem of surface wrinkles:

Reduce the amount of glue applied, adjust the angle of the pressure wheel, and reduce the speed of profile wrapping.

4. The edge of the profile falls off after wrapping:

It may be that the pressure wheel does not press the edge enough, the soil temperature is too low, the wrapping material is overstretched, the hair dryer is not heated enough, and the pressing time is too short.

How to solve the problem of edge detachment:

Adjust the angle of the pressure wheel, increase the temperature of the sol machine, reduce the tension of the wrapping track on the material, increase the temperature of the hair dryer, and reduce the speed of profile wrapping.

How to choose hot melt adhesive for Pur profile wrapping

Bonding requirements

Different substrates and wrapping materials will affect the performance and key parameters of the glue (viscosity, open time, curing conditions, tensile strength, etc.). After determining the bonding requirements, be sure to communicate with the glue supplier promptly to provide the appropriate Pur wrapping hot melt adhesive model for use.

Small batch testing

To ensure that the glue is suitable for the on-site production process, it is recommended to ask the supplier to provide the glue for small batch testing before mass production to understand the actual bonding performance of the Pur profile wrapping hot melt adhesive.

Green and environmental protection

As the environmental protection policy requirements of various countries are getting higher and higher, before using glue, you need to understand with the Pur profile wrapping hot melt adhesive supplier whether the glue contains solvents and VOC emissions and ensure that it can pass environmental protection testing standards such as ROSH, EU Reach, and US FDA.

Supplier Qualifications

Understand the production scale, R&D capabilities, application experience, after-sales capabilities, etc. of the Pur profile wrapping hot melt adhesive supplier, which will be related to the stability of your subsequent use of the glue and the timeliness of the service.

Price

The price of glue is related to the overall cost of the finished product, but price is not the only criterion for choosing glue. Factors such as the adhesive properties and quality stability of the glue also need to be considered.

In summary, when choosing pur profile wrapping hot melt adhesive, you need to focus on factors such as bonding requirements, small batch testing, green environmental protection, supplier qualifications, and price. Zhongshan Blue Rhino New Material Co., Ltd. is a Chinese supplier with more than 10 years of experience in the application of hot melt adhesive for profile wrapping pur profiles. If you have any questions about profile wrapping your profiles, you can consult us and we will answer them for you immediately.