Labeling glue is mainly used to adhere labels to glass bottles, plastic bottles, and other packaging so that manufacturers can display the name of the product and provide detailed instructions for use. Its application industries are also very wide, but in daily life, we generally see it more in the packaging of condiment bottles, beer bottles, and beverage bottles.

But if you are a manufacturer, you may be more concerned about how to choose the appropriate labeling glue. The following will analyze how to choose the appropriate labeling glue from the common types of labeling glue and their respective advantages and disadvantages:

1. Common labeling glue types

Distinguished from the chemical type of the product, there are three main types of labeling glues currently used on the market, namely: oil-based labeling glue, water-based labeling glue, and hot-melt labeling glue.

From the perspective of gluing methods, these three types of glue can be adapted to manual gluing and machine gluing; if the machine gluing method is used, higher bonding efficiency can also be achieved (50,000 glues can be bonded per hour) More than one label on the bottle), and can also achieve the effect of breaking the material (that is: after the label is bonded to the bottle, the label is peeled off, and the label paper can be seen bonded to the bottle).

2.Advantages and Disadvantages of Oily Labeling Glue

Oil-based label adhesive is mainly an adhesive made from organic solvents, and the most common one is oil-based adhesive. It is a composite label made of paper, film, and other materials as the label fabric, with oil-based adhesive applied on the back in advance, and then a layer of protective paper as the backing paper.

The main advantages of self-adhesive are:

1.A wide range of label fabrics can be bonded. Because solvent-based glue has good penetrating properties, coated paper, PVC, PET, PP, and various special papers can be bonded.

2.The high and low-temperature resistance effect is very good. Since many food packages will be placed in the refrigerator or outdoors, the adhesive needs to have excellent high and low-temperature properties. Oil-based adhesives can achieve this effect very well.

3. The bonding effect of the finished product looks more high-end because many types of labels and base materials can be bonded. Therefore, many high-end wine packaging bottles and condiment bottles will choose to use oil-based labeling glue.

The main disadvantages of self-adhesive are:

1.It is not environmentally friendly enough. To have better adhesive performance and range, organic solvents are added to the adhesive. Some solvents even have toxicity, which is not very friendly to users and the environment.

2. The cost is relatively high, and compared to water-based adhesive, the cost of sticking labels alone is more than 3 to 5 times higher; Simply put, it means sticking a label with oil-based adhesive. If you switch to using water-based adhesive, you can stick at least 3 to 5 labels, or even more.

3. Advantages and disadvantages of water-based labeling adhesive

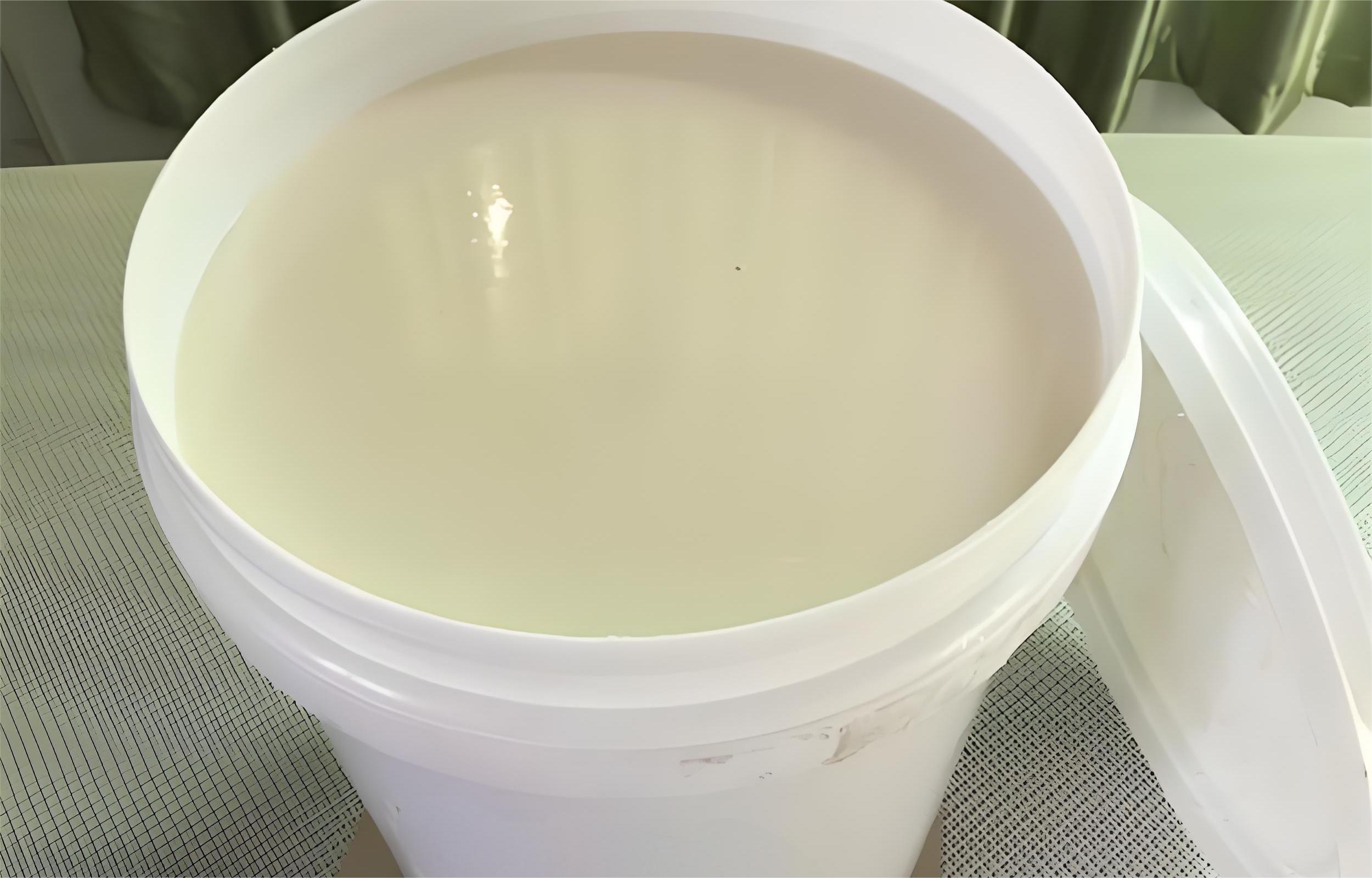

Adhesive products made with water, emulsion, and other solvents can be called water-based labeling adhesives. When using glue to label, you can apply it on coated paper and plastic film, and stick it on glass bottles and plastic bottles. Its products are mostly used in beverages, food factories, industrial product factories, etc. Both manual gluing and machine gluing can be used. For smaller factories, hand gluing is also very convenient.

Advantages of water-based labeling glue:

1.Green, environmentally friendly, and low pollution. Since the main components of water-based labeling glue are water and environmentally friendly emulsion, etc., both the glue itself and the bonded paper substrate are more convenient to use than solvent-based glue. It is safer and more friendly, and it is also more conducive to its degradation in the environment.

2.Low cost. As mentioned above, water-based glue is the lowest-cost type among labeling glues, only 3 to 5 times that of other glues. Since FMCG products are used in relatively large amounts, this cost savings is one of the factors that manufacturers have to consider.

3. Good high-temperature resistance. Because of the product’s characteristics, its high-temperature resistance is much better than hot melt adhesive.

Disadvantages of water-based labeling glue:

1.The adaptability range is slightly smaller. Since the product does not add non-environmentally friendly water-based solvents, it can only bond paper and plastic labels.

2. The low-temperature resistance effect is average. This is mainly due to its chemical characteristics, but it can also reach minus 10-20°C, which can also meet the manufacturer’s needs.

4. Advantages and disadvantages of hot melt labeling adhesive

Labeling adhesives that use resin as the main raw material and add other auxiliary agents in a high-temperature melt state can be called hot-melt labeling adhesives. The product is mostly used for bonding labels made of bopp material to PET bottles and is most commonly used for mineral water bottles in the beverage industry.

Advantages of hot melt labeling adhesive:

1.Green, environmentally friendly, and low pollution. Like water-based labeling adhesive, since its main raw material is resin, it is friendly to users and the environment.

2.The curing time is fast. Compared with water-based labeling adhesives, curing can be completed as long as the temperature of the product drops to normal temperature.

3. Low cost. The cost is slightly higher than that of water-based labeling glue, but much cheaper than oil-based labeling glue.

4. Excellent low-temperature resistance due to the chemical properties of its resin.

Disadvantages of hot-melt labeling glue:

1.It is inconvenient to operate manually because the glue needs to be heated to a molten state through a heating device, which is more troublesome than other types of glue.

2.The high temperature resistance is average. Because the hot melt adhesive reaches a certain high temperature, the product will melt again. This is also caused by the characteristics of the resin raw material.

3. It cannot be used to bond paper to glass bottles, mainly due to the poor permeability of resin to glass.

For the product introduction of the above three types of labeling glue, before choosing glue, you can evaluate its corresponding advantages and disadvantages, and then make a choice based on the actual needs of the product.