Vacuum membrane press glue is a water-based polyurethane adhesive, mainly used for bonding PVC membranes to medium-density fibreboard and particle board surfaces. It is mostly used in cabinet factories, door factories, audio factories, and some furniture manufacturing factories. In recent years, vacuum blister doors are becoming increasingly popular among consumers because they are cheaper than solid wood doors and their styles and colors are also popular among young people. However, many manufacturers do not operate in a standardized manner, resulting in pitting on the surface of the products after vacuum blister products are blistered.

Next, I will share with you the main reasons and solutions for pitting on the surface of vacuum plastic products.

1. Use unqualified vacuum plastic

If the particle diameter of the vacuum membrane press glue itself is large, and then a thin (less than 0.15mm) PVC film is used for bonding, pitting will easily appear on the product. The characteristic of such pitting is that it is evenly dispersed on the entire sheet. In this case, you can ask the glue supplier to choose glue with a smaller particle diameter and replace it with a thicker PVC film.

2. The hardener is not mixed evenly

If glue is used together with hardener, the hardener is not stirred evenly during mixing and stirring to make it completely dispersed, resulting in pitting on the board. Given this situation, the manufacturer will appropriately extend the stirring time (more than 2 minutes) when mixing the hardener so that the hardener can be completely dispersed in the glue.

3. The surface of the board is contaminated by dust

The board was not polished before the vacuum membrane. If there is no dust removal equipment in the workshop, it is also possible that the board was contaminated by dust after spraying the vacuum membrane. The characteristics of this pitting are very uneven and of different sizes. Given this situation, if the workshop has the conditions, a dust-free workshop can be set up. Sandpaper can be used to polish the board before the vacuum membrane, and compressed air can be used to blow away the dust on the surface.

4. The density of the board is too low

If the density of the board is too low (less than 800kg/m³), the glue will be sprayed onto the board and the edges will be fuzzy. Such pitting usually occurs in grooves or corners and occurs in large quantities. In this case, you can choose a board with a higher density and use glue with a higher solid content to prevent the board from swelling after too much glue is absorbed by the board.

5. The caliber of the spray gun is too large, and the worker sprays the glue unevenly

If the caliber of the spray gun used by the worker is too large and the worker cannot spray glue evenly on every place on the board, it will also cause pitting on the final product. In this case, it is necessary to strictly follow the glue use standards, the caliber of the spray gun should be between 1.5-2.0mm, and the glue should be evenly applied (60-70g/m²on the flat surface, 80-100g/m² on the sides and grooves).

6. The glue has been used for too long, resulting in a film on the surface

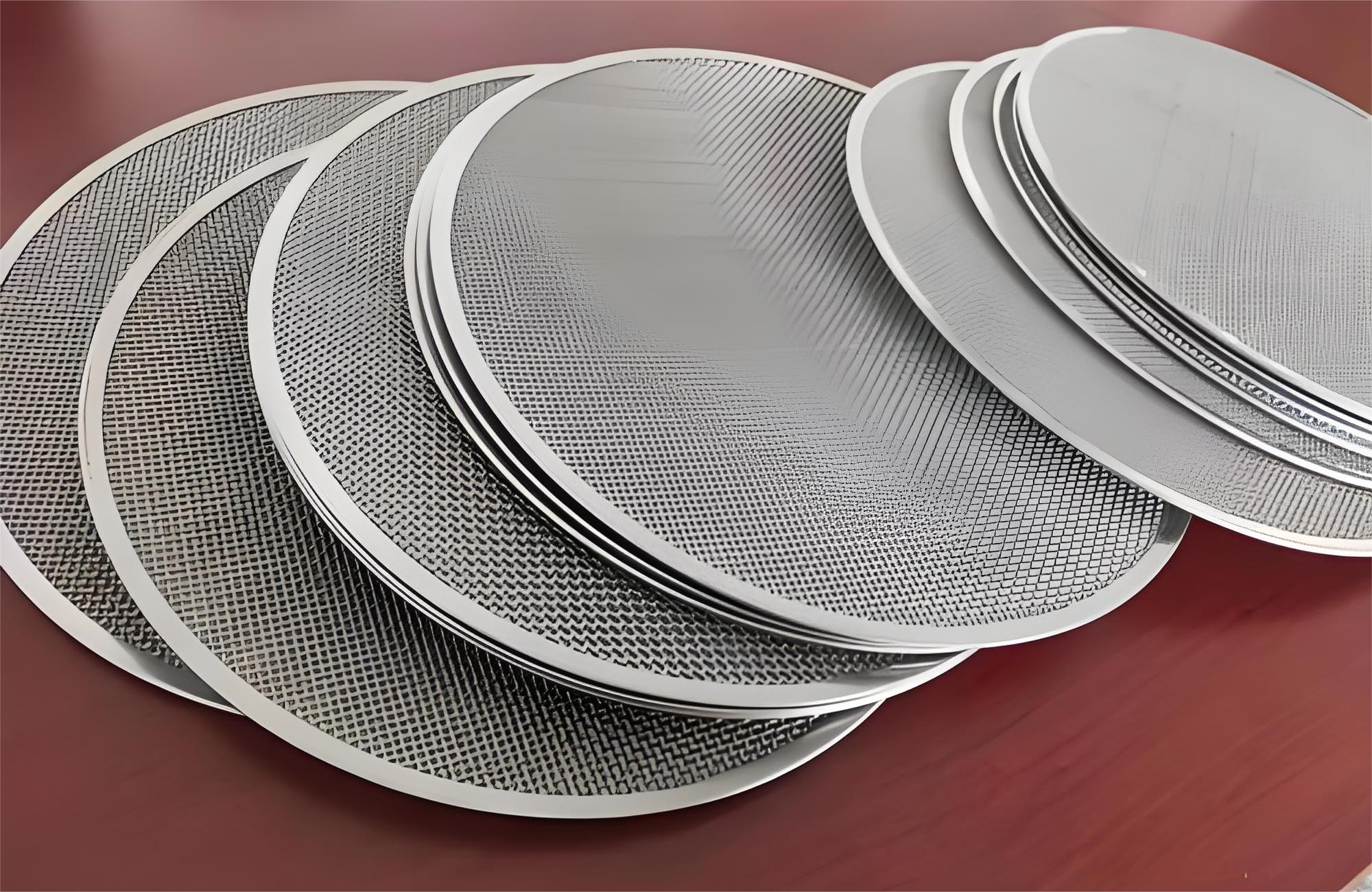

If a bucket of glue is opened and not used up for a long time, a film will form on the surface. If this glue is used to bond products, it will easily cause pitting on the surface. In this case, we recommend that the unused glue be sealed. If a film is formed, it can be filtered through a filter before use.

The above 6 reasons are the main reasons why pitting appears on the surface of the product during our daily use of vacuum membrane press glue. Everyone should improve it according to their on-site conditions. If you have any questions, you can consult us.