Most panel furniture factories use Eva hot melt adhesive for furniture edge banding; compared with traditional water-based white glue, Eva hot melt adhesive uses different chemical properties according to the product’s: sol temperature, bonding substrate temperature, board moisture content, machine edge banding speed, glue application pressure, glue application amount and many other matters need to be paid attention to, otherwise, the bonded products are prone to weak bonding, false adhesion, etc.

Let me share with you eva Some precautions for using edge-banding hot melt adhesive:

1. Sol temperature

When using glue, you first need to put it into the machine’s sol furnace to sol it before it can be used. However, the temperature in the glue furnace needs to be strictly controlled. If the temperature is too high, the glue will be carbonized, thereby changing the glue properties and affecting the bonding ability; while the temperature is too low, the hot melt adhesive cannot be completely liquefied, which will also affect the wetting degree of the glue and the bonding strength.

According to the edge banding speed of the machine, the glue can be divided into high-temperature glue, medium-temperature glue, and low-temperature glue. The corresponding temperatures are as follows:

High-temperature hot melt adhesive (edge banding speed: above 25 M/min): 180-210℃

Medium-temperature hot melt adhesive (edge banding speed: 20-25 M/min): 150-180℃

Low-temperature hot melt adhesive (edge banding speed: below 20 M/min): 120-150℃

2. Bonding substrate temperature

When edge banding is performed in winter or when the ambient temperature is low, if the molten hot melt adhesive comes into contact with low-temperature panels or edge banding, it will easily cause the glue to partially solidify on the surface due to a significant drop in temperature, thus affecting the Its bonding effect and penetrating power, so before bonding, it is necessary to ensure that the temperature of the board is above 15°C (the board and edge banding can be heated by baking or hair dryer heating) before it can be used normally. If conditions permit, the edge banding process can be carried out in a constant temperature and humidity workshop.

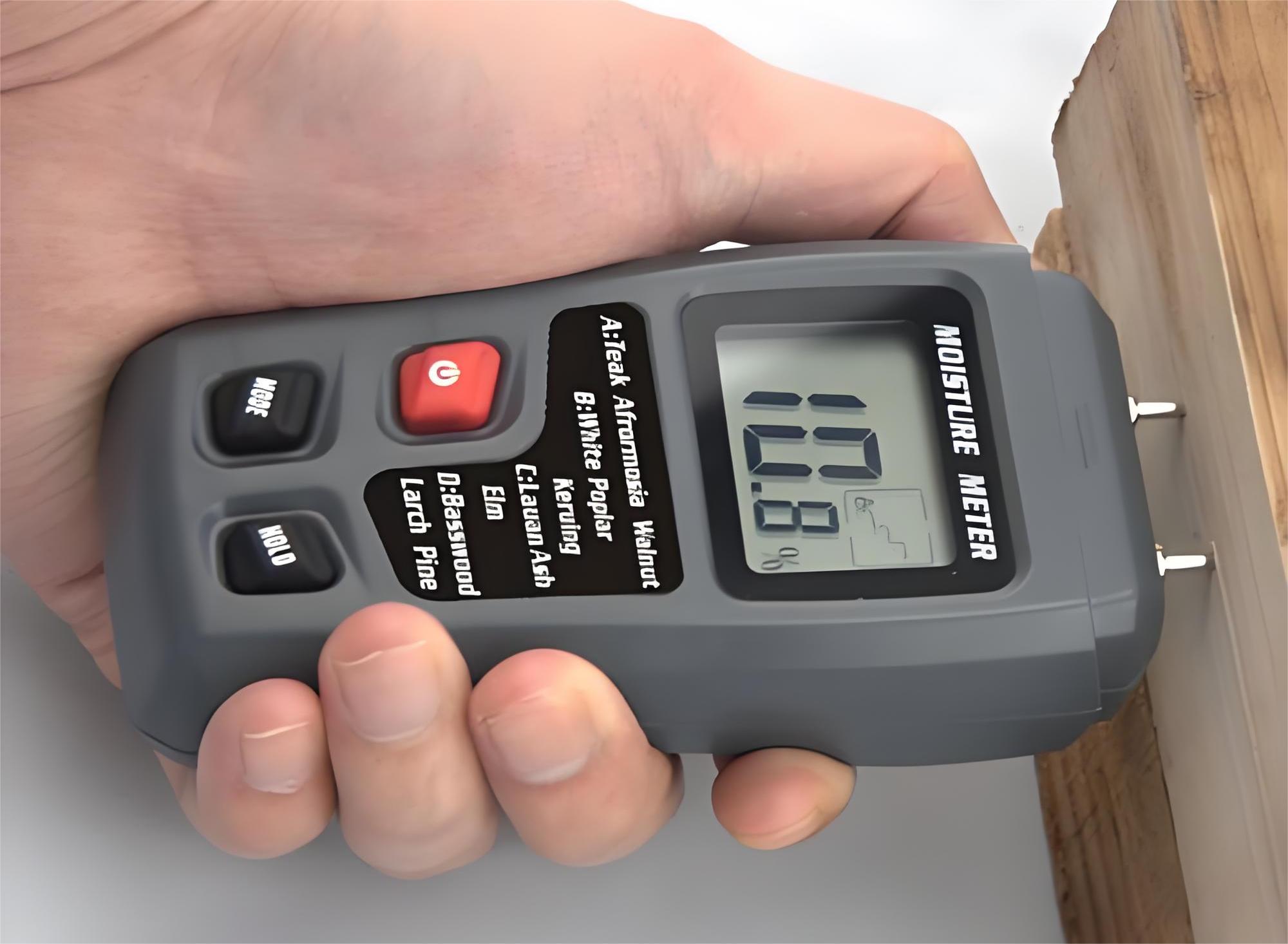

3.Board moisture content

If the moisture content of the bonded boards is too high (more than 12%), it will cause the high-temperature EVA hot melt adhesive to come into contact with the board, causing the moisture of the board to atomize and evaporate, resulting in the formation of a layer of water vapor located between the adhesive and the substrate, hindering the penetration of the adhesive into the board and affecting the bonding strength.

4. Machine edge banding speed

The edge banding speed of the machine will also affect the glue bonding effect. If the edge banding speed of the machine is too slow, the EVA hot melt adhesive will be exposed to the air for too long, and the temperature of the glue will not reach the bonding temperature during edge banding, Penetration and adhesive strength will also decrease.

5. Gluing pressure

Under normal circumstances, the better the liquid state of the EVA hot melt adhesive, the smaller the required pressure wheel pressure. On the other hand, if the glue does not melt in place and becomes semi-liquefied, and the pressure of the pressure wheel does not meet the standard, the bonding effect will also be affected. To allow the glue to have better penetration, it is necessary to ensure that the temperature of the melting furnace and the pressure of the pressure wheel reach the standard.

6. Gluing amount

The amount of glue applied must also be consistent. If the amount of glue applied is less, the surface of the base material cannot be fully bonded and the strength is insufficient. However, the amount of EVA hot-melt glue should not be too high. If it is too high, it will easily lead to glue overflow at the edge of the edge. When the painting process is carried out, the glue will expand when it encounters the paint, which will affect the final edge banding effect.