Polyvinyl acetate emulsion adhesive has excellent water resistance and heat resistance, excellent performance in filling audio assembly, strong bonding strength, meets EU D2 waterproof standard, and can pass GB/T 18583-2008, ROHS, REACH, phthalate 17P and other tests.

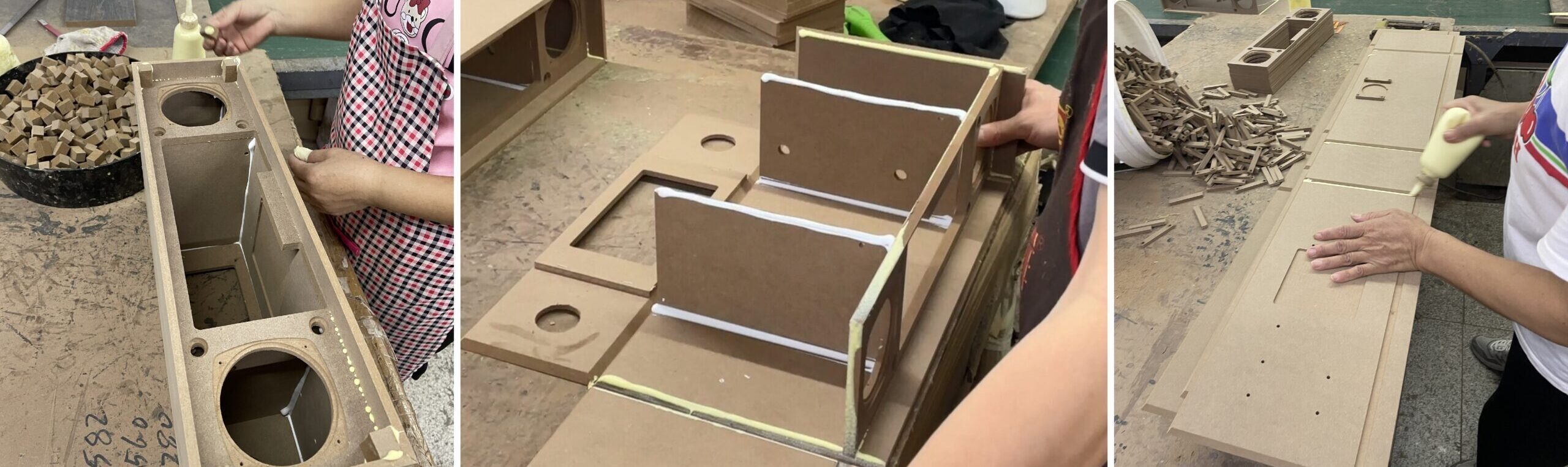

Application :90 degree angle and V groove assembly of particleboard and medium density fiberboard used in audio manufacturing, etc.

Glue amount:180-250 g/m²(too high a glue coating amount will result in slow curing speed, too low a glue coating amount will result in lack of glue and affect the bonding strength).

Operating ambient temperature:15-35℃ is the best, and the air humidity should be kept at around 50-75% (high temperature cures faster, low temperature cures slower; high humidity cures slower, low humidity cures faster).

| Color | white, yellow |

|---|---|

| Gluing method | Machine gluing, Manual gluing |

Special glue for speaker assembly, can be applied by hand or machine, good filling effect at the bonding point.

Good solvent resistance, high and low temperature resistance, excellent permeability, ideal bonding speed.

1、With 20 years of experience in adhesive research and development, our technical engineers have a thorough understanding of bonding substrates and gluing processes, greatly improving your production efficiency.

.png)

2、In order to ensure the stable quality of the adhesive, all raw materials used come from international chemical giants, such as: LG Chem, Celanese, Dow Chemical, BASF, Sinopec

3、18 fully automatic intelligent glue production lines, with an annual output of more than 50,000 tons, and sufficient inventory to ensure that goods reach customers on time.

4、Our adhesives have SGS, VOC, ROHS, ISO9001 and other test reports to ensure that the glue is safe and environmentally friendly.

5、We have many years of experience in international logistics and transportation, and are familiar with sea shipping, land transportation, air transportation and other methods, so you don’t have to worry about glue transportation.

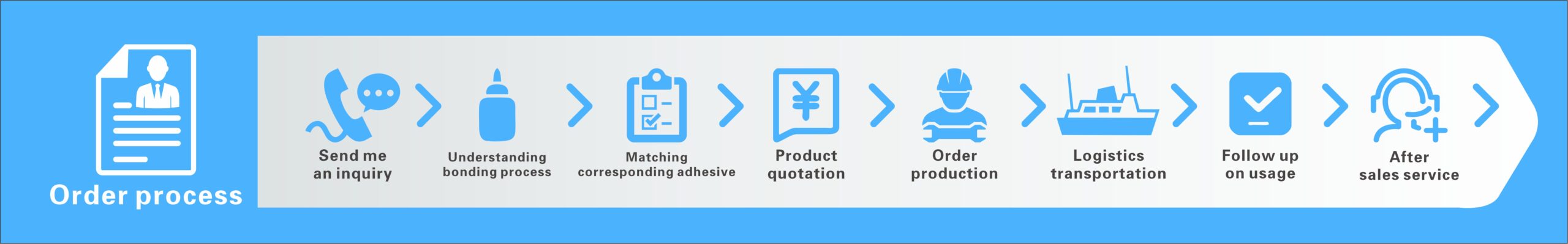

Receive your message, we will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.

A factory with more than 10 years of adhesive experience will answer your questions

Phone and wechat: +86 137 0239 0495

Email: sales@bluerhino-adhesive.com

We will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.