Nowadays, many furniture, especially office furniture, wardrobes, and cabinets, are made of artificial boards. At the same time, edge-banding hot melt adhesive is also used to seal the edges of the boards to ensure the aesthetics of the product and increase the water resistance and weather resistance of the product. However, many manufacturers are not particularly clear about the board parameters and requirements before edge banding. Below, we will share with you what requirements for boards before using edge-banding hot melt adhesive:

1. Do not choose boards containing grease

Generally, glue needs to penetrate the substrate to form glue nails and achieve the required adhesive strength. Therefore, when using hot melt adhesive for edge banding, the selected board should not contain too much grease, because oily boards will reduce the affinity with glue, and it is difficult for the glue to penetrate oily boards, resulting in insufficient strength and easy-to-fall off naturally after a long bonding time.

2. Ensure the board temperature is above 10°C

Before edge banding, the temperature of the board and edge banding materials must be above 10°C. Especially in winter when the ambient temperature is relatively low, the board and edge banding strips must be properly heated before using edge banding hot melt adhesive for edge banding (consider producing in a constant temperature workshop and using edge banding heating plates), otherwise false adhesion or debonding may occur.

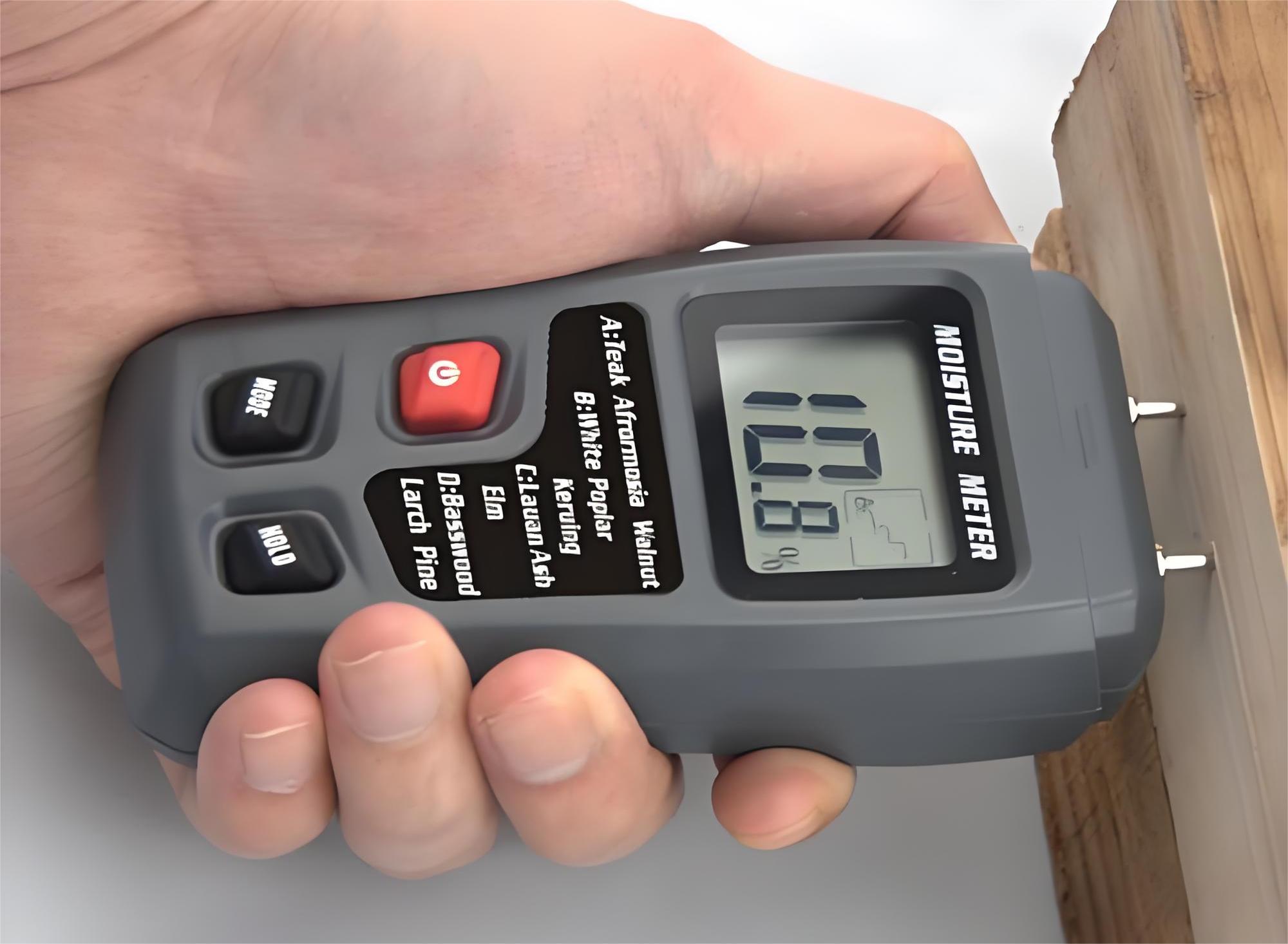

3. Ensure the moisture content of the board is between 6-12%

The moisture content of the board must be controlled between 6-12%. If the moisture content of the board is too high, the hot melt adhesive will solidify prematurely during the edge banding process, and false adhesion or debonding may occur. Therefore, we recommend that manufacturers use a wood moisture meter to test the moisture content of the board before edge banding and control the overall humidity of the workshop between 40-75.

4. Ensure the sides of the board are flat and smooth

Edge banding hot melt adhesive is mainly applied on the side of the board, so make sure the side of the board is flat and smooth. If there are bumps on the board, it is easy to cause a lack of glue at the bumps, and it cannot be properly bonded to the edge banding material, resulting in false adhesion or debonding.

5. Fireproof panels need to be pre-treated

If you choose fireproof board as the edge banding material, if there is residual material on the side of the fireproof board, it will also affect the effect of edge banding. Therefore, it is necessary to use appropriate solvents for pre-treatment in advance, so that the effect of edge banding can be guaranteed.

Therefore, to ensure that there are no problems with the edge banding of the board after we use the edge banding hot melt adhesive, the manufacturer must meet the above 5 requirements to ensure the production of good quality furniture.