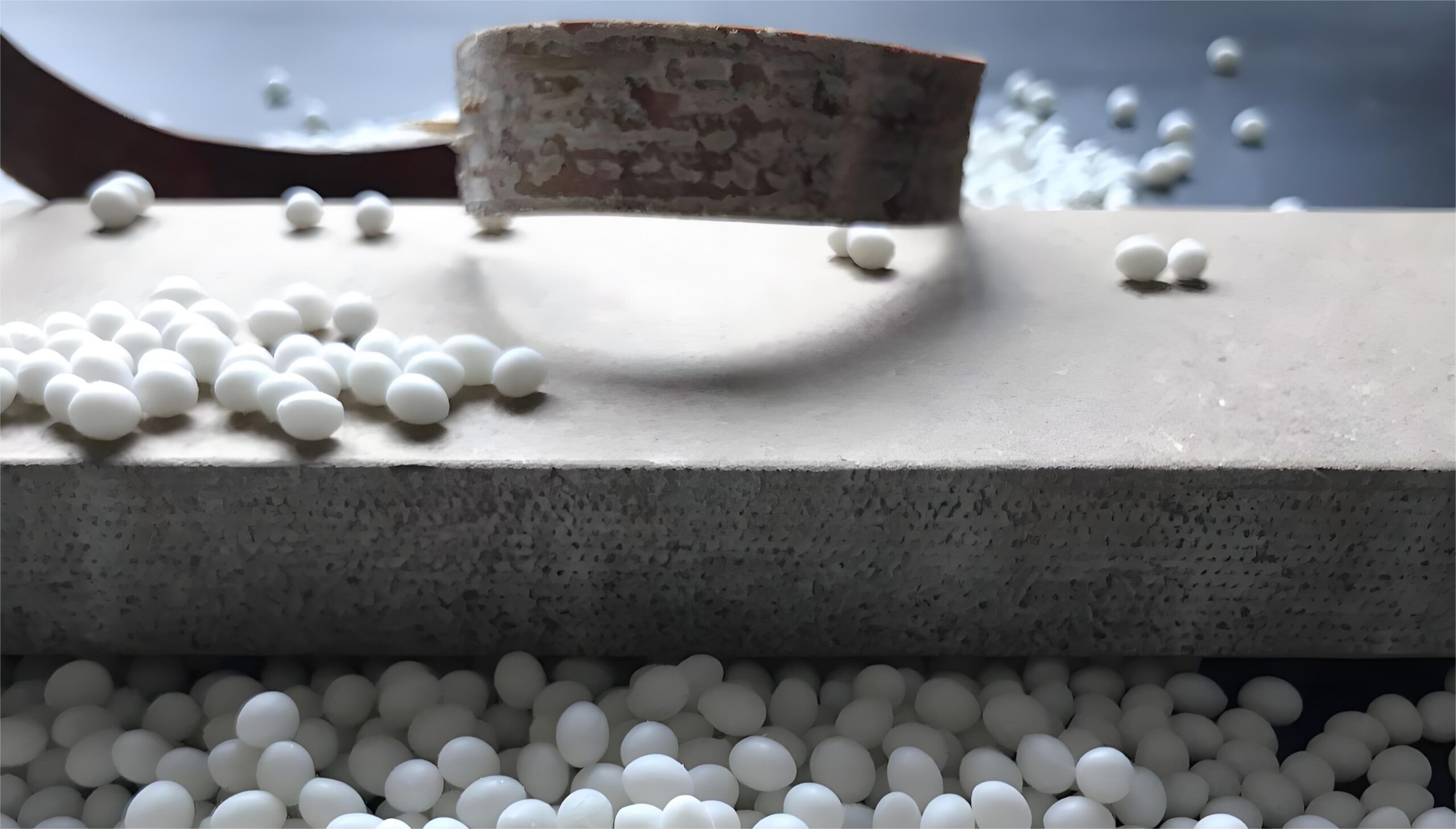

Through our observation and analysis of the furniture market over the years, we have found that the hot melt adhesive used by furniture factories for edge banding of panels accounts for a large proportion. The mainstream edge banding hot melt adhesives are mainly EVA edge banding hot melt adhesive and PUR hot melt adhesive. However, based on the overall usage, the EVA edge banding hot melt adhesive is still the most used in furniture factories. EVA edge banding hot melt adhesive is a heat-curing hot melt adhesive. Compared with PUR edge banding hot melt adhesive, water-based white glue, or oil-based glue, it is a reversible adhesive.

The bonding principle of EVA edge banding hot melt adhesive is to melt the glue from solid particles into liquid through the glue pot, apply it to the board or edge banding material, and then the glue changes from liquid back to solid, forming a bonding process. It seems that the use of hot melt adhesive is straightforward, but there are still many things to pay attention to (such as the use temperature of the glue, the temperature of the edge banding material, the speed of the edge banding machine, the pressure setting, and the amount of glue applied, etc.), otherwise, the edge banding material of the finished product will easily fall off. Next, I will share with you what you should pay attention to when using EVA edge banding hot melt adhesive:

1. The use temperature of glue

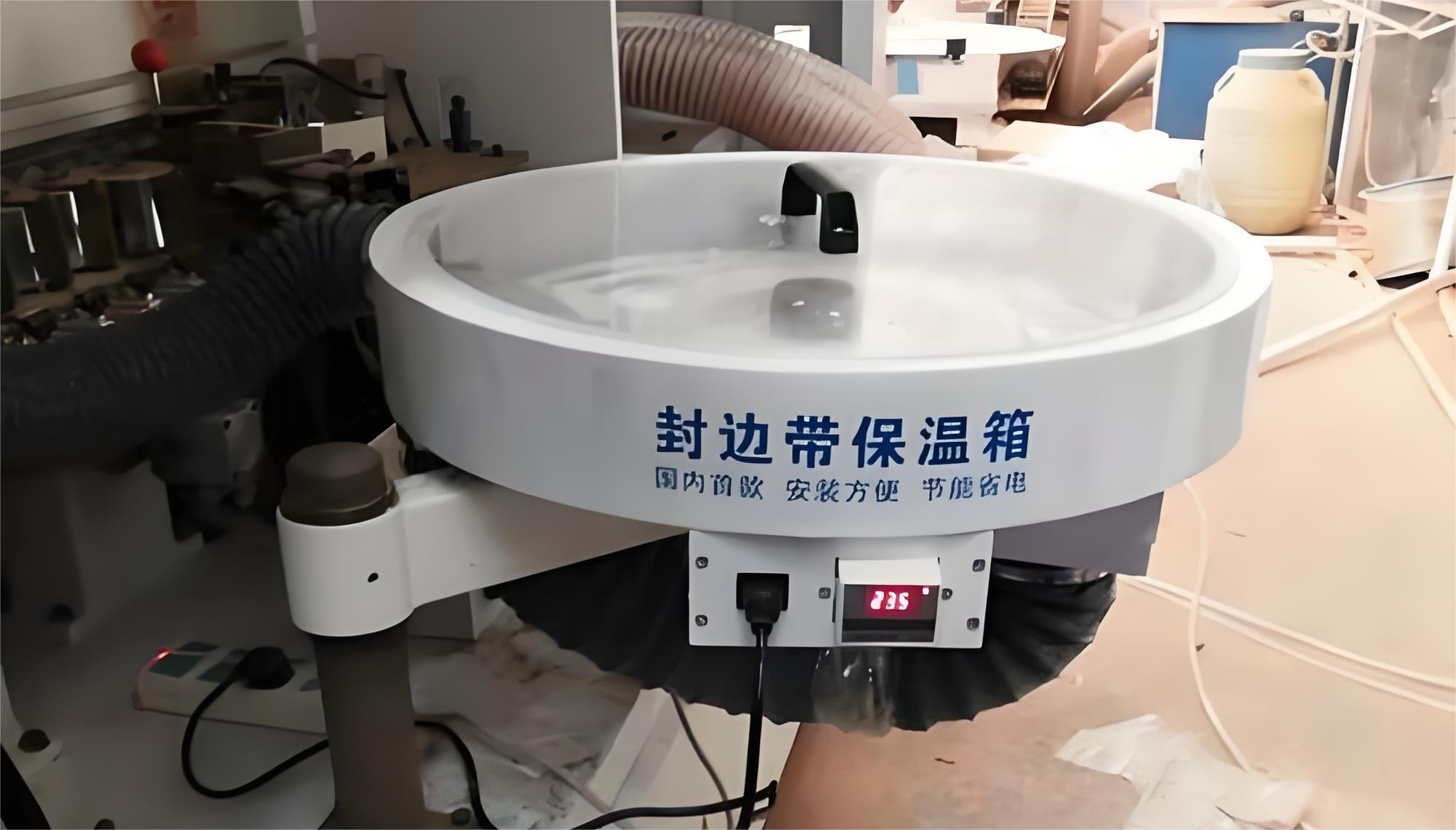

When using hot melt adhesive, manufacturers generally use semi-automatic or fully automatic edge banding machines, and these machines have at least one sol glue pot (some equipment has two glue pots, one of which serves to preheat the glue). Before using the glue, it needs to be placed in the sol glue pot for high-temperature melting before it can be used for edge banding in the machine. Therefore, before using, manufacturers must confirm whether their hot melt adhesive is a high-temperature hot melt adhesive (180-210°C) or medium-temperature hot melt adhesive (150-180°C) based on the edge banding speed of their edge banding equipment.

When using, the soil temperature must be set strictly according to the temperature requirements; if the set temperature is too high, the glue may carbonize in the glue pot, affecting the bonding strength. If the temperature is set too low, the hot melt adhesive cannot be completely melted into a liquid state, which can easily lead to failure to fully penetrate the board, which will also affect the final bonding strength.

2. Actual temperature of edge banding material

In winter when the ambient temperature is relatively low if the edge banding materials (PVC edge banding strips, veneer edge banding strips, etc.) are used directly without heating treatment, it is easy for the glue to drop to an extremely low temperature instantly after contacting the low-temperature edge banding materials, which will also cause the glue to fail to completely penetrate the board, or a film has formed on the surface before bonding, which will also affect the final bonding strength.

Secondly, the edge banding materials are also prone to become brittle in a relatively low-temperature environment, affecting the bonding with the glue. Therefore, when manufacturers use EVA edge banding hot melt adhesive at a relatively low ambient temperature, it is recommended to use a heating device to properly heat the edge banding materials.

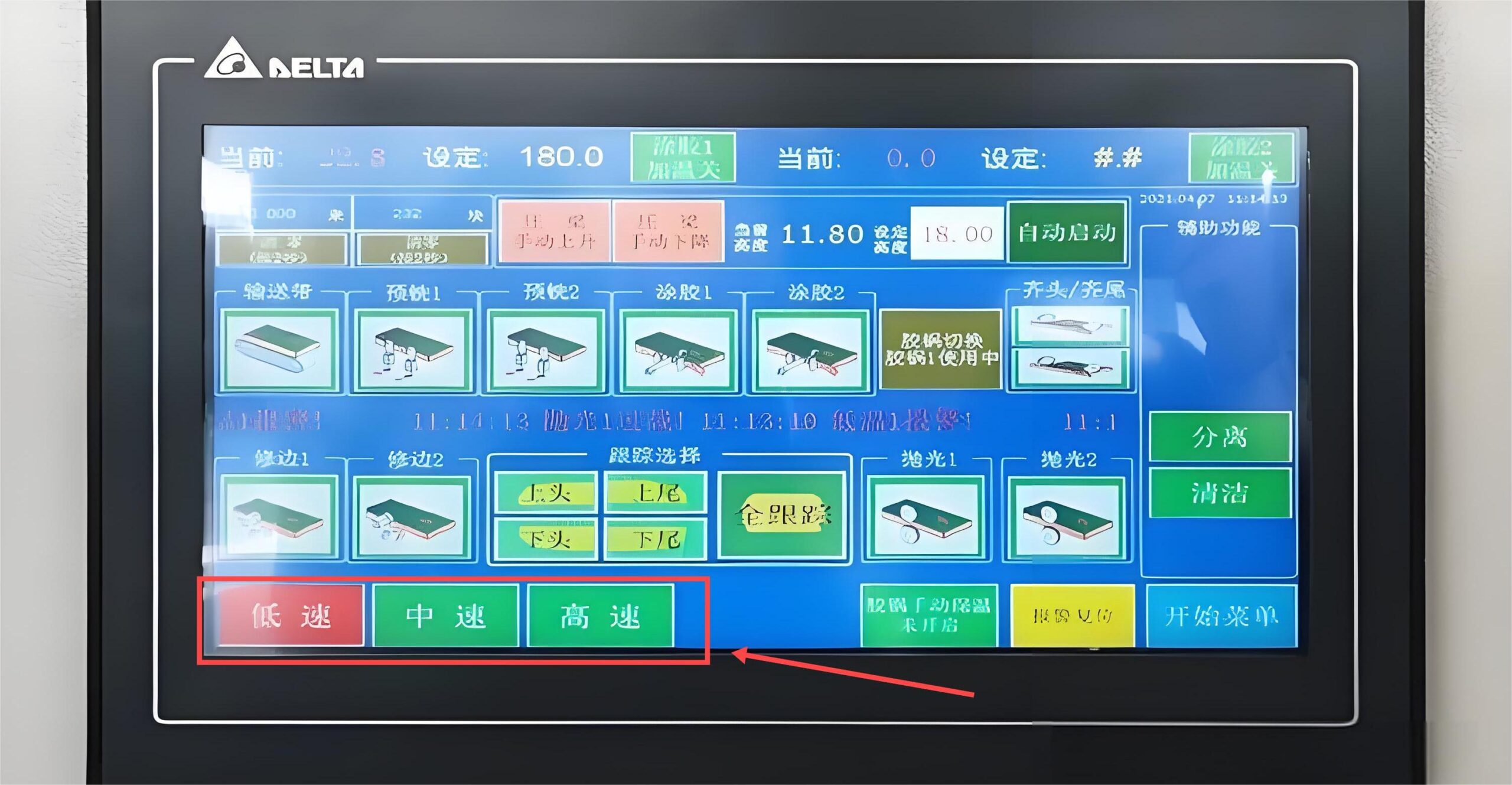

3. Speed setting of edge banding machine

The speed setting of the edge banding machine mainly considers the production efficiency and the maximum edge banding speed of the machine itself. The intelligent fully automatic edge banding line is much more efficient than the semi-automatic production line and has higher requirements on the bonding performance and melting rate of the glue.

If the edge banding machine speed is relatively slow and the open time of the glue is relatively short, it is easy to cause the exposure time in the air to be too long. By the time the edge is banded, the glue temperature has not reached the bonding temperature, which will also affect the penetration performance of the glue and lead to a decrease in the adhesive strength. Therefore, if the edge banding speed of the machine is 20-25 meters/minute, you can choose medium-temperature hot melt glue; but if the edge banding speed is above 25 meters/minute, you need to choose high-temperature hot melt glue.

4. Pressure setting of edge banding machine

Based on our experience, the better the melting state of the EVA edge banding hot melt adhesive, the better the corresponding glue wetting and penetration properties will be. Therefore, the pressure requirement for the edge banding machine’s pressure wheel will be smaller. On the contrary, if the ambient temperature is relatively low, to allow the glue to better penetrate the board, the machine’s pressure wheel pressure can be appropriately increased. At normal temperature (15-30°C), the pressure on the contact surface of the pressure wheel is recommended to be controlled at 3-5kg/cm.

5. Glue application amount

The amount of EVA edge-banding hot melt adhesive (150-220 g/m2) must be used strictly according to the manufacturer’s recommendations. If the amount of glue applied is too little, the surface of the board and the edge-banding material cannot be fully bonded, which can easily lead to insufficient final bonding strength. However, if the amount of glue applied is too high, it is easy to cause a large amount of excess glue to overflow from the finished product. When the painting process is carried out, the glue bonding point will have the risk of expansion when encountering paint, affecting the final bonding and aesthetic effect of the finished product.

The above 5 points are what furniture manufacturers need to pay special attention to when using EVA edge banding hot melt adhesive. If you have other questions about edge banding hot melt adhesive in actual production, you can consult us.