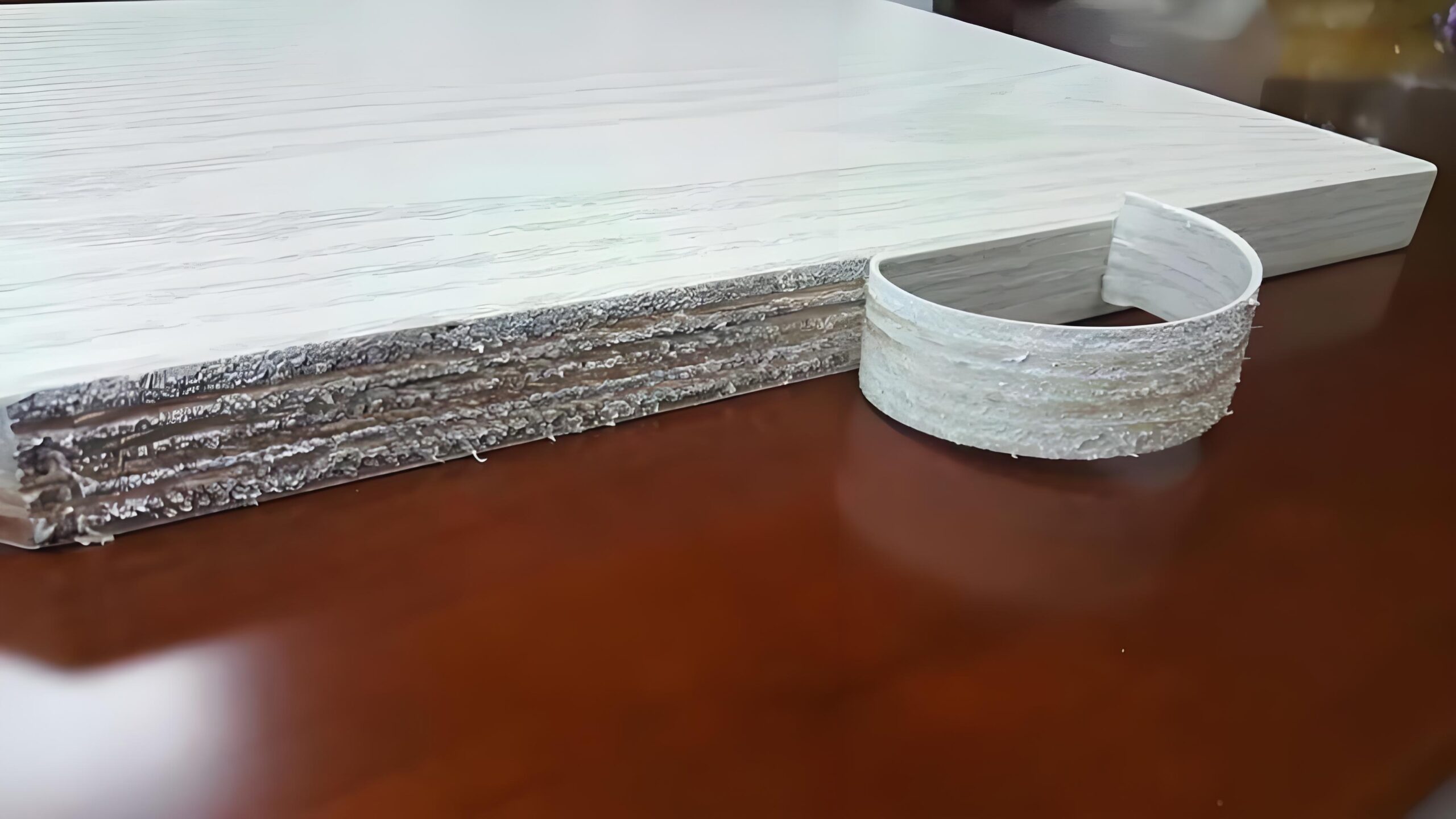

Nowadays,to make furniture more beautiful and durable, furniture manufacturers generally use EVA hot melt adhesive for edge banding or profile wrapping. However, in daily use, there are some details that manufacturers need to pay attention to at all times. If these details are not paid attention to, it is easy to cause debonding or false adhesion. Below, I will share with you these details of EVA hot melt adhesive:

1. Is the working temperature correct

Generally speaking, the operating temperatures of EVA hot melt adhesive are mainly divided into three types:

1、high-temperature hot melt adhesive (180-210℃)

2、medium-temperature hot melt adhesive (150-180℃)

3、low-temperature hot melt adhesive (120-150℃)

High and medium temperatures are mostly used in fully automatic or semi-automatic machines (edge banding speeds above 20m/min can be called medium- and high-speed machines), and low-temperature hot melt adhesive is mostly used manually.

When using the product, the heating temperature of the machine must be strictly set. It should not be too high or too low. Too high a temperature will cause the glue to burn and carbonize, affecting the bonding performance; too low a temperature will prevent it from reaching a molten state, affecting the effect of coating on the substrate.

2.Is the sol equipment cleaned daily

As the hot melt adhesive edge banding machine or wrapping machine needs to work for a relatively long time every day, it is easy for some unused hot melt adhesive to accumulate in the glue tank. If there is no regulation to carry out daily cleaning, the carbonized glue at the bottom will easily become sticky during future use, affecting the wrapping or edge banding effect.

3.Gluing machine should avoid blowing

In the production workshops of some furniture manufacturers, we often see edge banding machines placed near windows or vents. When the hot melt adhesive flows out of the glue tank, it is blown directly by the vents, and the temperature of the hot melt adhesive will drop instantly. In serious cases, the glue will not be applied to the board, and it will solidify prematurely, affecting the final bonding strength, and resulting in false adhesion or debonding at the edge.

4.Avoid excessive dust in the working environment

As we all know, wood processing workshops are generally dusty. If there is too much dust on the edge of the substrate or the wrapping, it is easy to cause gaps in the glue bonding area, which makes it impossible to fully bond with the substrate, affecting the bonding strength.

Therefore, before edge banding or wrapping, the surface of the board should be cleaned and the board should be flat. At the same time, the dust in the working environment of the operation workshop should be controlled to ensure a good bonding effect.